LEWIS SPRING HOUSE

BUILT

1954

CLIENT

George Lewis II

ARCHITECT

Frank Lloyd Wright

ADDRESS

3117 Okeeheepkee Road

The house plan was the first of two “pod-shaped” homes that Frank Lloyd Wright had designed throughout his entire career. The Spring House is currently the only private residence that was designed and built in Florida by Frank Lloyd Wright. The home sits on ten acres of hardwoods in the Capital City of Tallahassee, Florida.

“The Mr. and Mrs. George Lewis II House is a two-story residence typical of Frank Lloyd Wright’s circular or “hemicycle” mode. It is situated in a wooded setting on the outskirts of the developed suburban area of Tallahassee and sits on a gentle slope overlooking a spring and a narrow stream.”[1]The house was designed during the same period as the Guggenheim Museum in NYC, and both the home and the museum are based on a confluence of arcs that make the two buildings similar and revolutionary.[2]

Figure 1 Ron Jones – Florida Division of Archives

George Lewis II was the president of The Lewis State Bank in Florida, which was the oldest bank and started in 1856. Clifton Lewis, the wife of George, was the one that approached Mr. Wright to design a house for their family. She had first met him at Florida Southern College In 1950 and this is where she had asked him to design their home. Mr. Wright had responded to her request with “find your ground, not on a lot, and get in touch.”[2] Mr. Wright would take on the project once the Lewises found a building site and sent him a map (topographical) of it. By 1952, Mr. Wright had completed plans for the Lewis House. The issue was not having an approved design but having someone capable of building the home with such a complex design with limited resources. The Lewises had to even set up a mill on the site in order to entice contractors to even consider taking on the project.

The site had a natural spring on the property that flowed to a lake nearby. I am sure that the location of the site please Mr. Wright. He had mentioned in his interview with NBC in 1958 that in the past twenty years of his life he was seeking a kind of refuge at the time… He mentioned that he was getting a worms-eye view of society and needed to get into the country. His mother had prepared a site for him and asked him to come and take it. His response was “I did and of course the countryside is southern Wisconsin low hills protruding rock ledges, wooded sight, and the same thing applied to Taliesin signified to, later on, to bear run. “The site determined the character and features of the house”

Mr. Wright was asked in his interview: “The American press and sections of your own profession have not always treated you kindly I just wonder if you have any comment about this?”

Mr. Wright had a strong response that is worthy of mentioning to better understand the Architect of the Spring House: “Well I don’t see any reason why they should have treated me kindly I was entirely contrary to everything they believed in and if that was right they were wrong why should they treat me kindly it was a question at one time I suppose of their survival or mine and in those circumstances you know what happens don’t you… it’s still happening in a way but not so much now but it is true that still, the greatest appreciation for what we’ve done comes from European countries and the Orient rather than from our own country we’re very slow to take things on that occurred at home it’s always been the idea of our people that culture came from abroad and they did can’t blame them for thinking so they didn’t want to hear this developing in the tall grass of the Western prairies that was not exciting in fact they’d rather resented hearing about it in that sense so hundreds had gone abroad and it had been understood and appreciated abroad and the Europeans came over here with it so they could sell it to the American people and they would take it from them when they didn’t like to take it from me.”

I was looking at the influences of this house during the same time, but before I get into what other discussions about the changes through time and what influences there were in art, culture, society, etc. it is important to know that one of his personal guiding thoughts in his life is the following. This quote is a response to this thinking about his work as it related to the influences of others on his work. “My idea was pretty well fixed I was pretty sure of my ground and my style and I saw no occasion you see early in life I had to choose between honest arrogance and hypocritical humility. I chose the former and have not seen a reason to change even now. They’re pursuing the same centerline to all changes and I’m confident that the principle of our work which is its heart and centerline is really the ideology of democracy. If democracy is ever to have a free architecture I mean if it’s ever to have freedom have a culture of its own architecture will be its basic effect and condition and I believe we have the centerline of that architecture for freedom and for democracy.”

Mr. Wright was a believer in Art and that Art could not be taught and that it could only be inculcated by exemplars. A guiding principle of his work was to navigate the site, occupants, and the needs of all parties in order to have a “pay-off.” His thoughts of the majority of Architecture were to have the effects sought and multiplied and the why of the effect the real cause of the center of the thing seems to have vanished. If Architects mastered the inner principle, an infinite variety would be the result. “No one would have to copy anybody else and my great disappointment in it all is that instead of emulation what I see is a wave of imitation.”

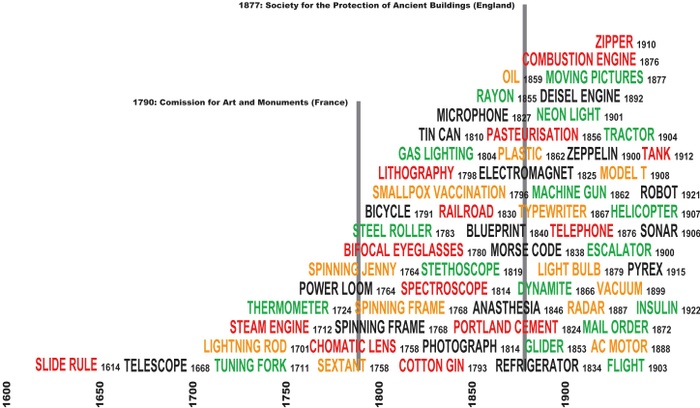

Historicism vs. Nostalgia

William Pahlmann, created furniture with casters in order to provide flexibility and adjustment within a room more easily. Pahlmann was at the forefront of color richness. He was proud of introducing, green, orange, deep cerulean blue for the lounge of the Columbus Hotel in Miami, driftwood, lime, orange, and white.

It is difficult to know what the furniture design was for the home. It was cited that Mr. Wright did design furniture, but the owners did not have it made. The only furniture that was integrated was built-in furniture, which is purpose-built to orient views outward. The existing furniture has a stark contrast to the flexibility that Mr. Pahlmann was designing at the same time.

There was also the development of other interior ideas from colors to fabrics, to textures, and even to the forms adjusting. The idea of sunken living space. A space created specifically for the integration of a family. This is in contrast to a building that is designed around multiple facets of life. A purpose-built space and in isolation of all other elements. This friction between Historicism and Nostalgia went as far as broadening the scope of an Interior Decorator. In 1957, NSID was founded, and there was reluctance to move away from Decorator to Designer. 1954 Federal Renewal Program. A slum meant any building over thirty years old. The federal renewal program was a specific program in order to motivate “design” for a political need. This act alone probably influenced statements from Wright about his disappointment with imitation over emulation. “No one would have to copy anybody else and my great disappointment in it all is that instead of emulation what I see is a wave of imitation.”

“If anything, good could stand in isolation, then it could stand next to anything else good.” – 1950’s viewpoint of quality

The interior spaces of the Lewis house were a composition of the whole… a family, a site, the function.

“Primary seating in the living room is adjacent to the fireplace on a low wood seat which runs the entire length of the west wall. This area is provided a strong sense of enclosure by the low ceiling under the second story, but the vista is toward a two-story space and the glass “rear” wall.

Interior decorative interest is provided by the natural colors, textures, and arrangement of the exposed structural materials. Only the ceilings are plastered and these are unpainted. All doors and operable windows are hung with exposed brass piano hinges; all other hardware is also of brass. All lighting fixtures are within 9″ square.”[1]

The home which has a plan of concentric and intersecting circles was atypical of common American building practices. The Lewis House was a radical statement within the historical architectural traditions of Tallahassee.

Mr. Wright objected to the idea of modernism in the sense of objecting and turning your back on something for subjective reasoning. Instead, the idea that Natural architecture should be the driver in the development of new forms. An emulation of the experiences and art that creates something new is important.

There is an entirely different way of approaching the Art of Architecture when you think of it holistically and respond to the site and the needs of the individuals. A lot of the reading on Historicism and Nostalgia are based not on the inner principles of the design, but on a motivator that is not connected directly to the needs of the occupants. I will once again leave you with the important descriptor of what it means to have Natural Architecture.

“Primarily the use of and sympathy with the site and nature of the ground and the purpose of the city and town whatever it might be and of course the character of the inhabitants in that connection… a natural architecture” – Frank Lloyd Wright

Mr. Wright had a belief that his most satisfactory achievement of his career would be his next building.

Figure 1 Photo by Ron Jones Florida Division of Archives

Bibliography

- Catalog.archives.gov. 2021. [online] Available at: <https://catalog.archives.gov/id/77842905> [Accessed 22 October 2021].

- “Lewis Spring House.” Frank Lloyd Wright Foundation. Accessed October 24, 2021. https://franklloydwright.org/site/lewis-spring-house/.

- National Broadcasting Company, and Encyclopaedia Britannica Films, Inc. 1958. Frank Lloyd Wright. National Broadcasting Co.

- Allen Tate and C. Ray Smith, Interior Design in the 20th Century, Chapter 15, pp. 421-442.

Week 5 – Sustainability / Equity Development

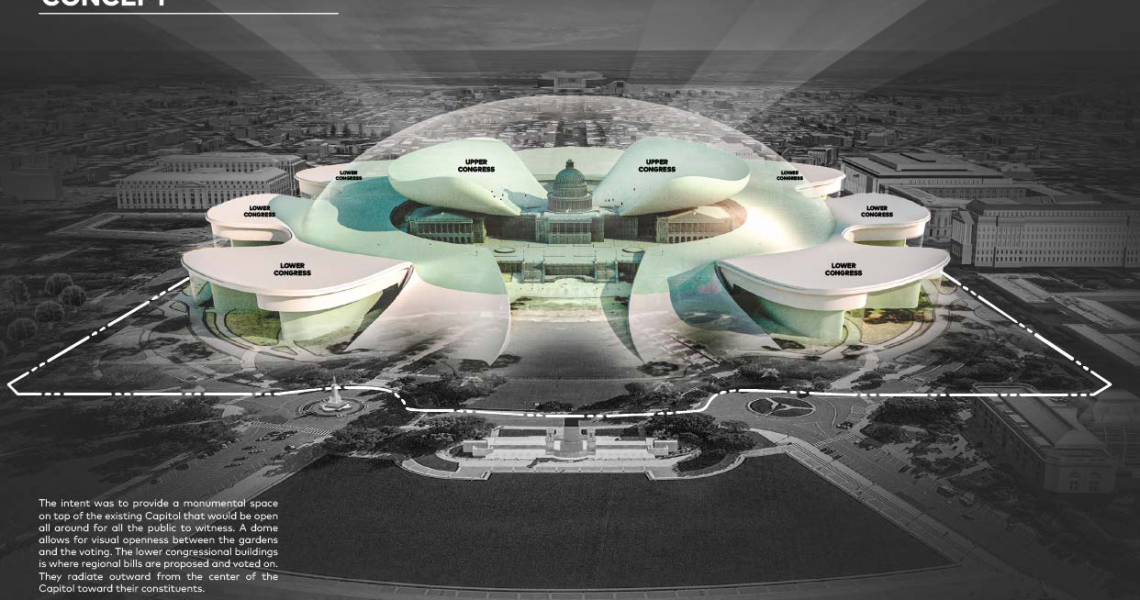

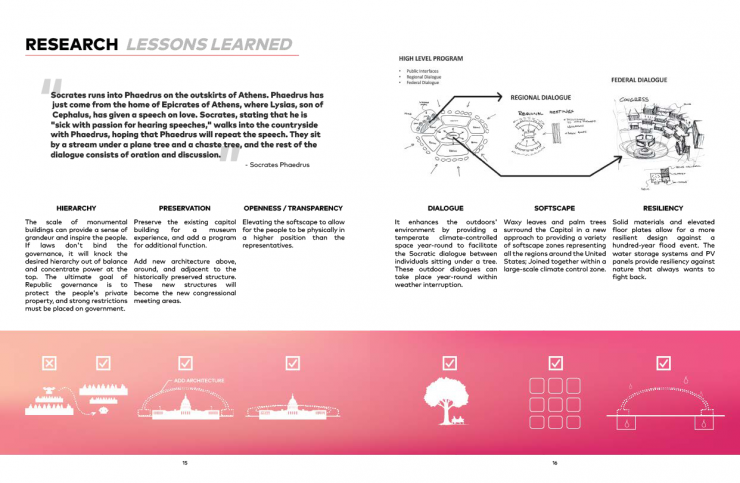

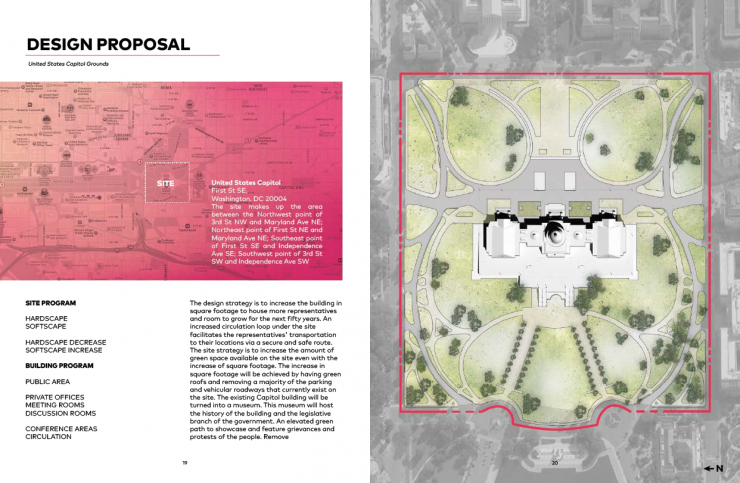

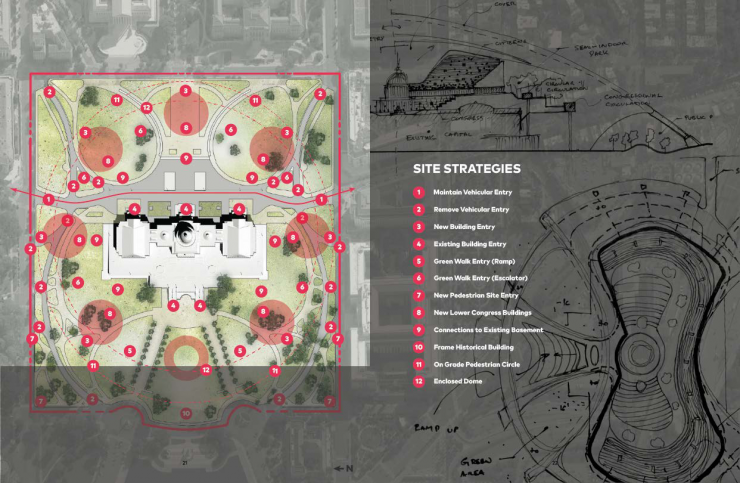

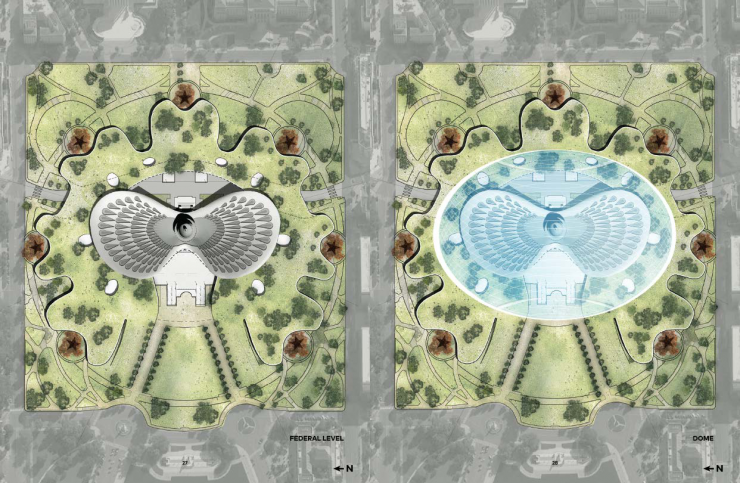

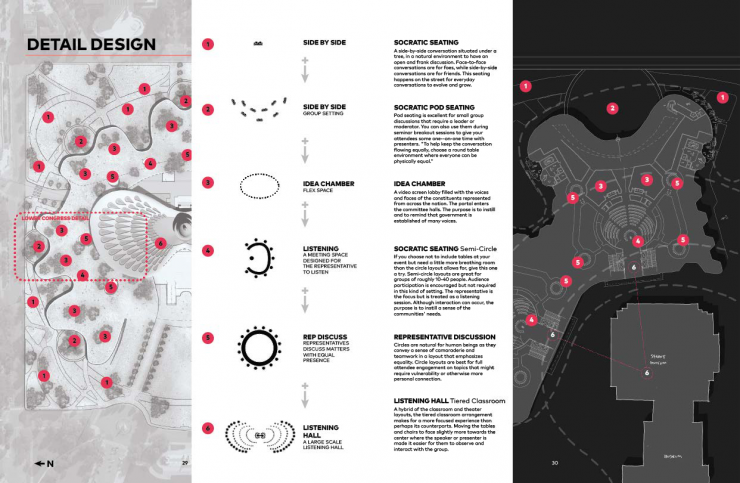

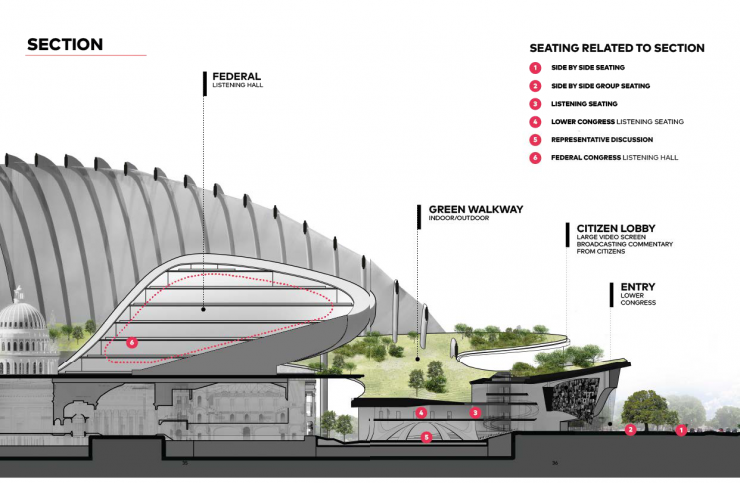

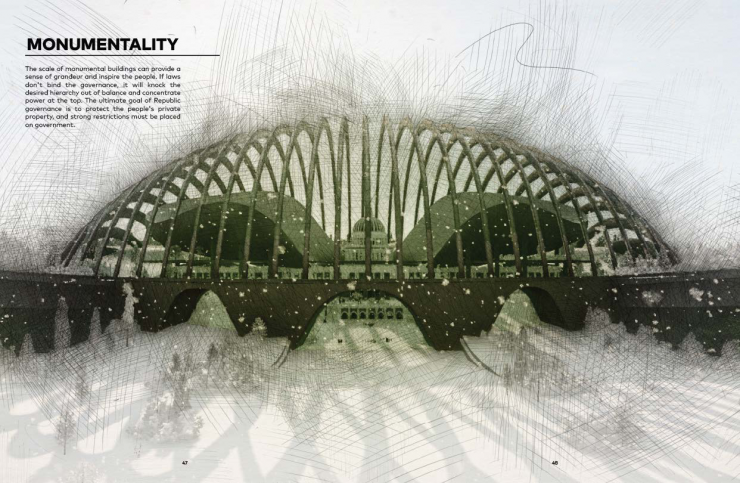

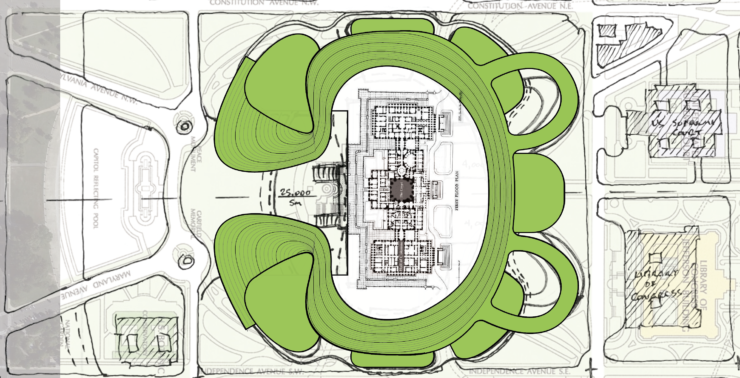

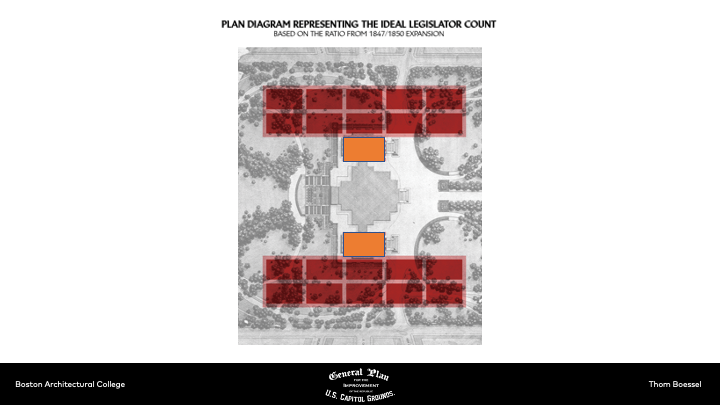

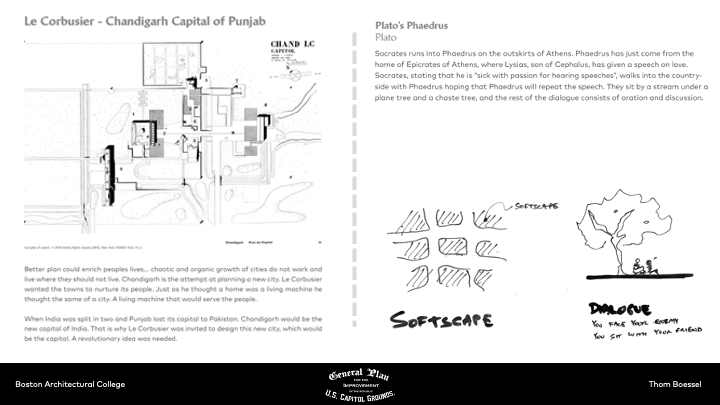

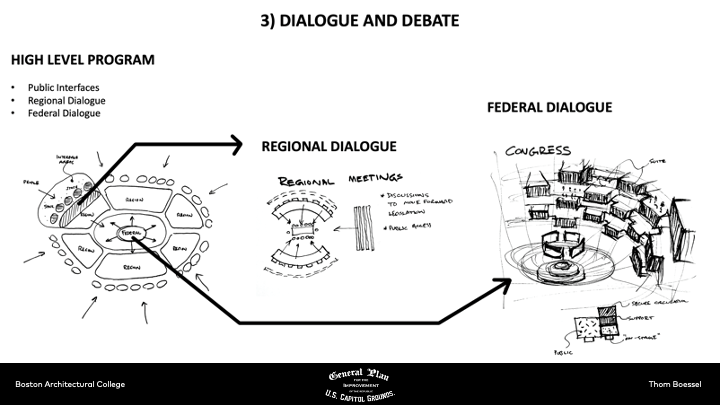

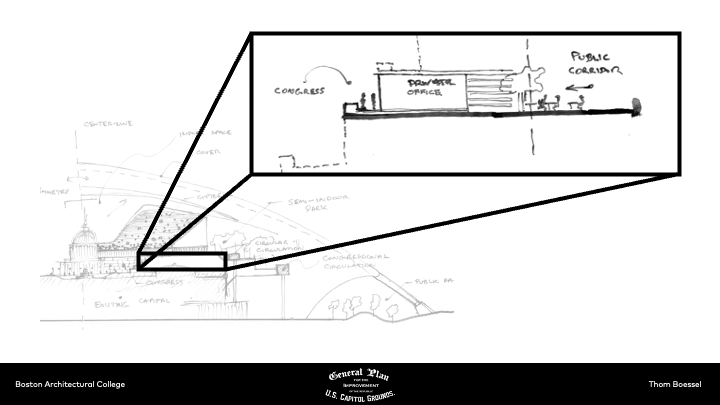

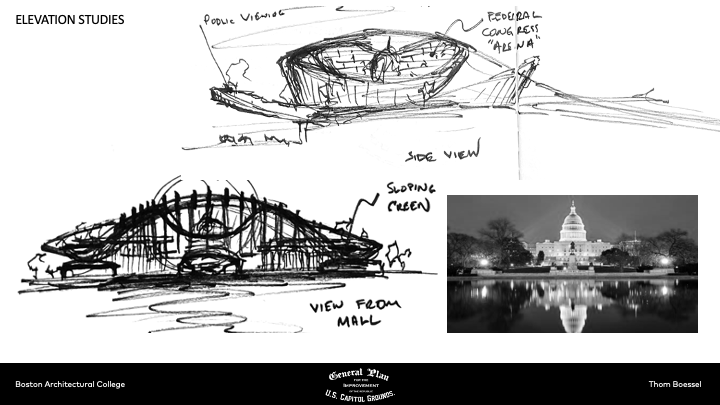

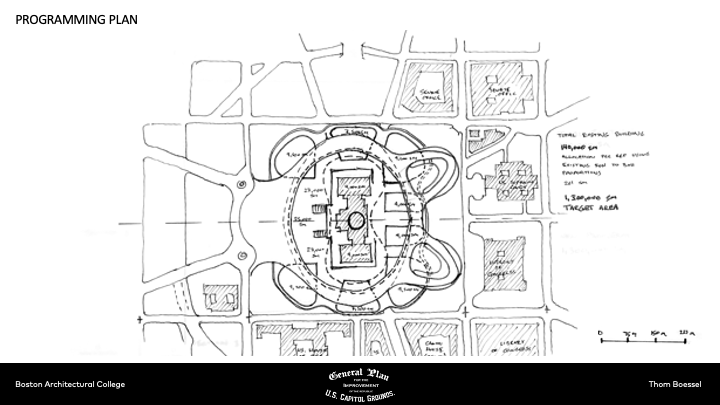

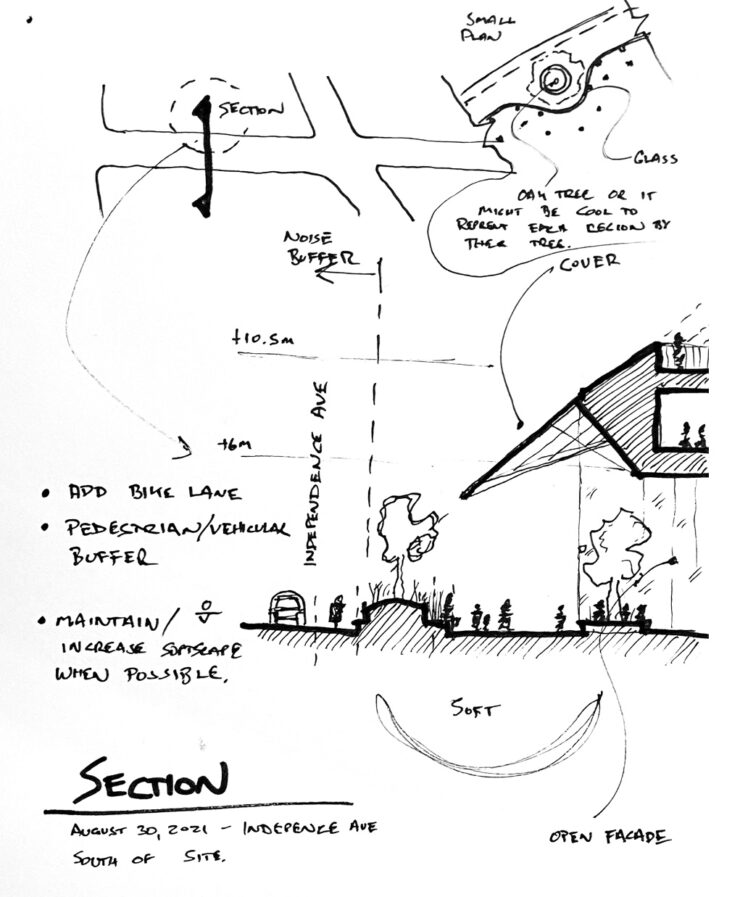

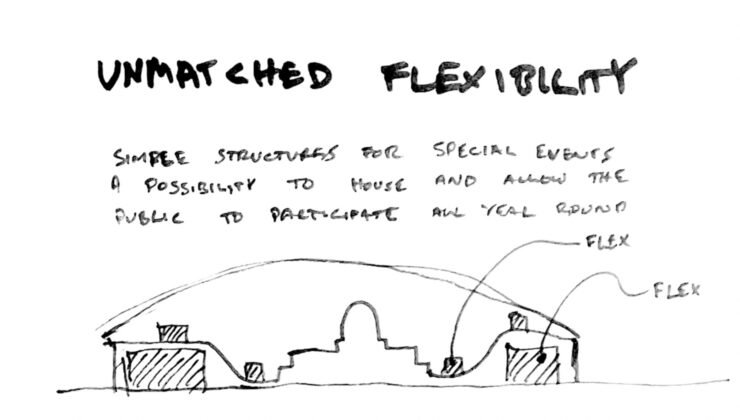

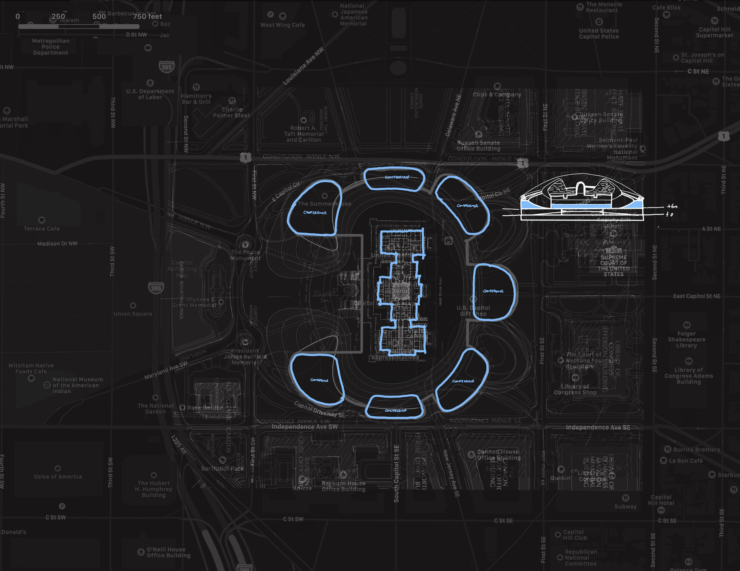

This week I spent time developing one of the edges of the street a bit further. I tried to include elements to make the space more resilient and equitable. The intent was to take higher-speed traffic and to group them. I took bikes and vehicles to live in a similar space. An elevated berm would buffer the slower pedestrian traffic, and the canopy from the dome would extend over these spaces to provide respite from inclement weather. At the entryway of each perimeter building, a formal space adorned by a large tree and seating arranged side by side captures the message of Socrates’ Phaedrus teachings. I intend to refer to these openings as dialogue gates, designed to encourage the passing traffic to pause and be encouraged to chat?

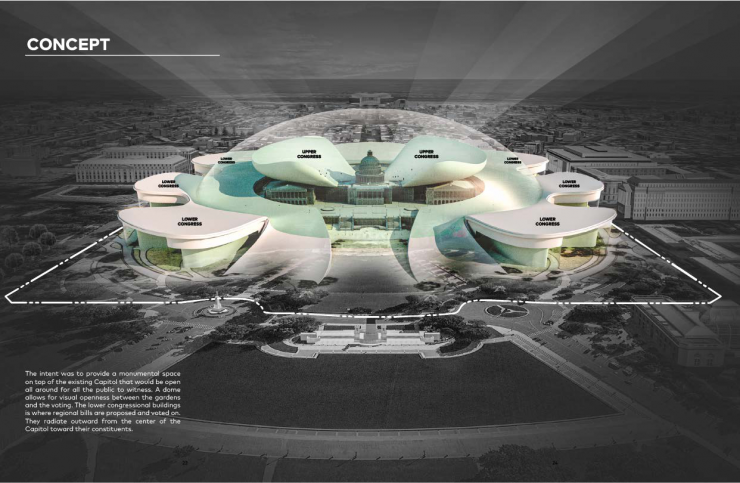

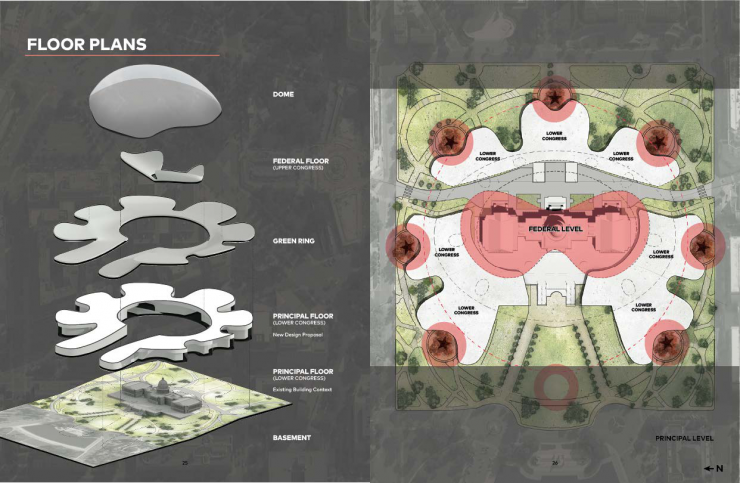

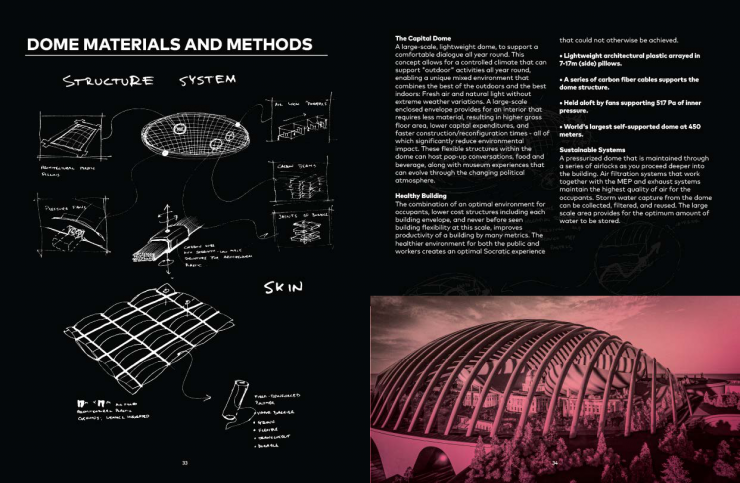

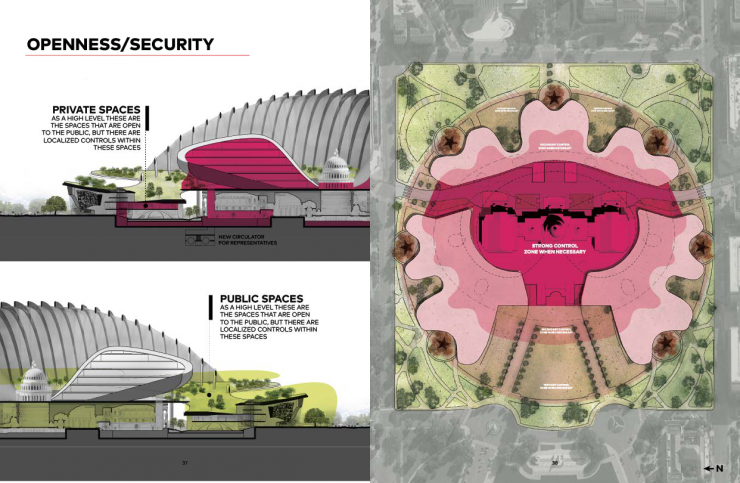

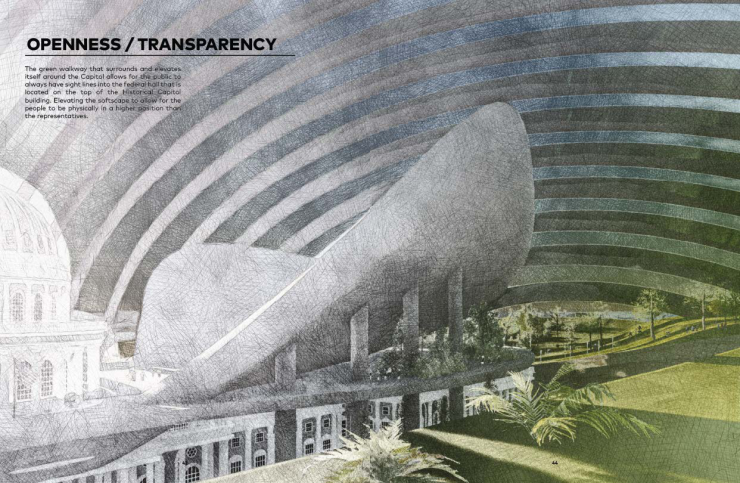

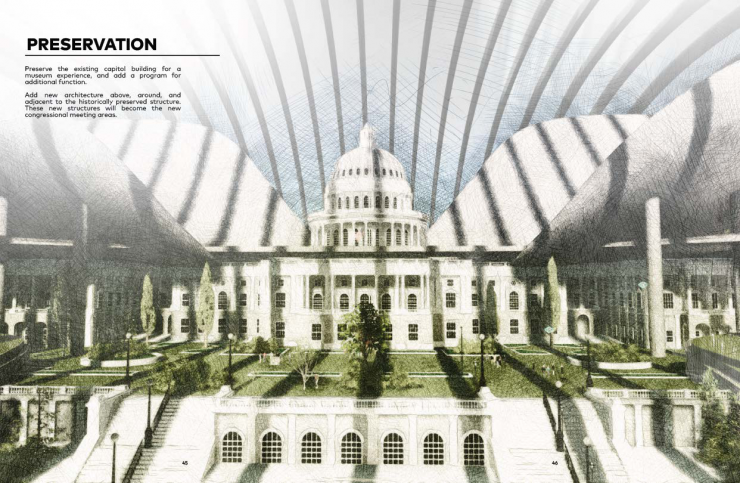

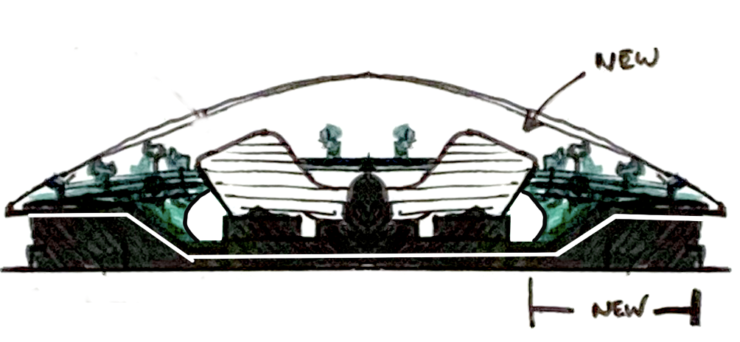

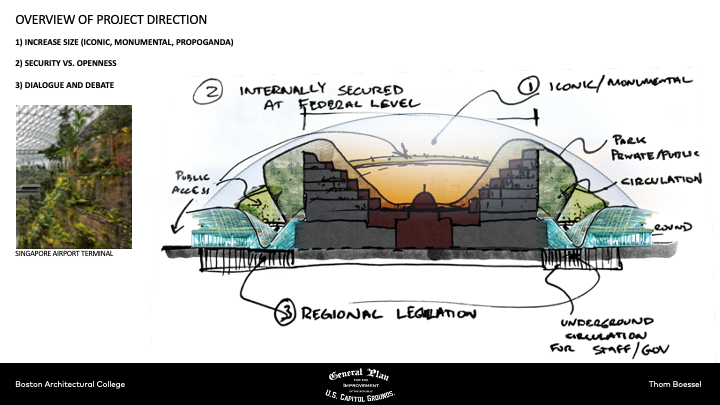

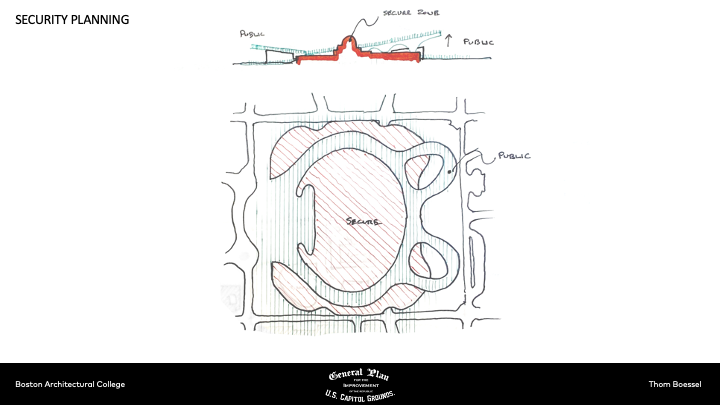

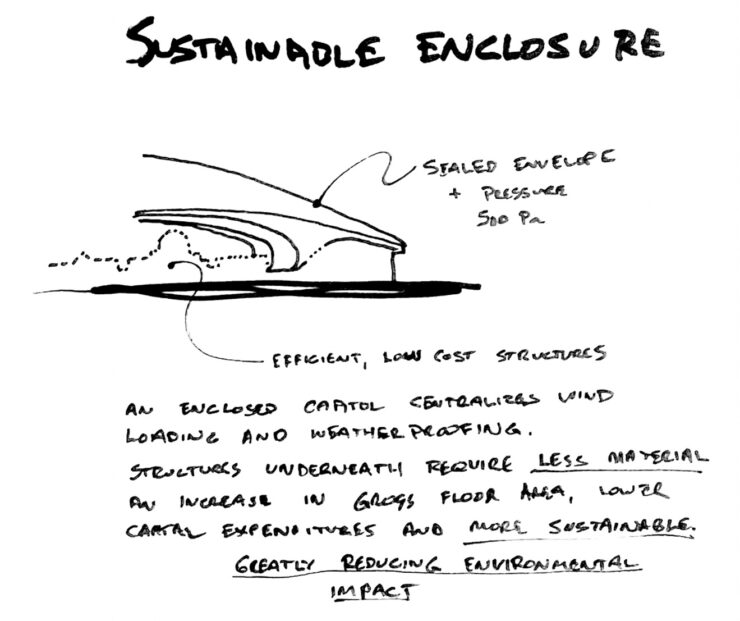

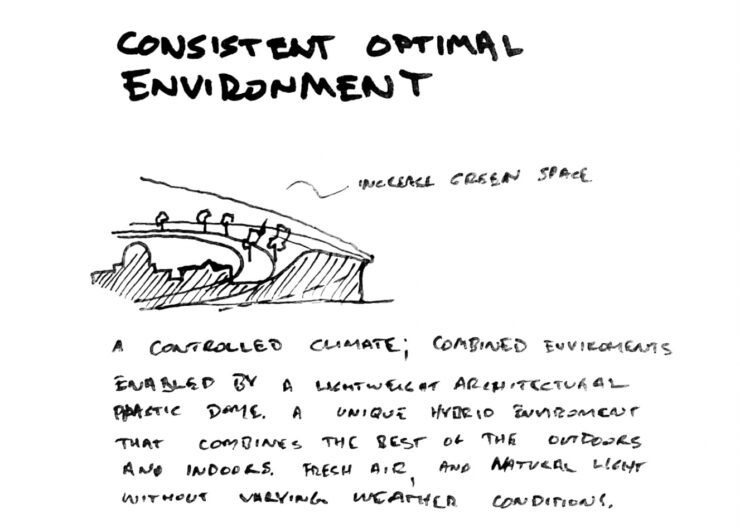

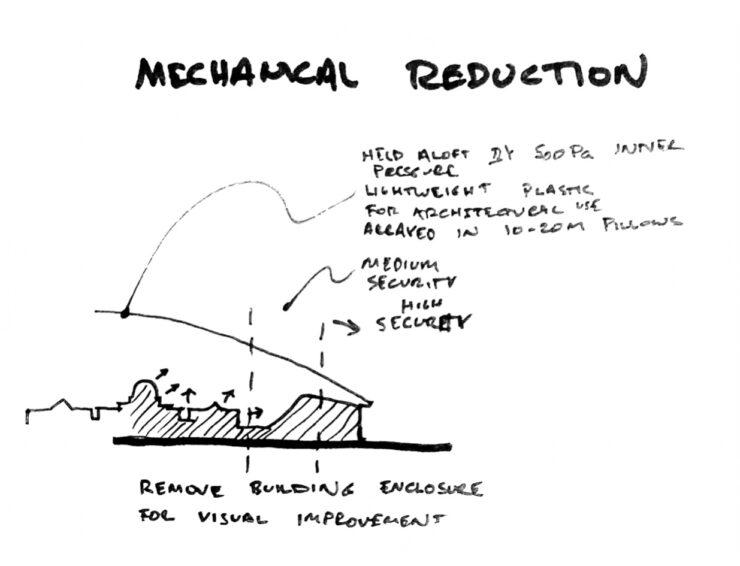

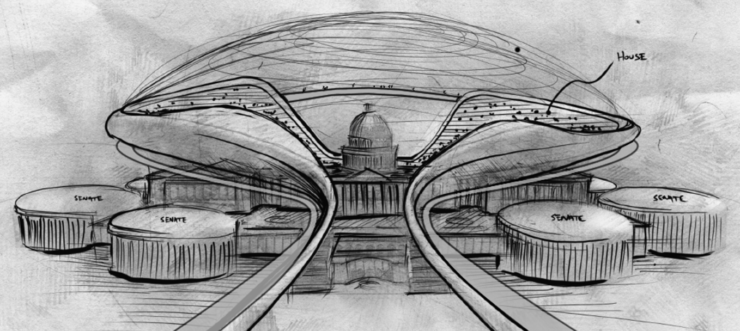

In terms of the preservation, there is a sensitivity to preserving the iconic façade and form of the existing building while adding the functionality that is proposed. The green space created will take on its own identity. The space that is created between the new buildings and the existing capitol building creates a new identity of blocking out the urban fabric from views within the capitol, which will allow for the respite that is required when having conversations with any real meaning. The dome connects the entire form as one space and protects the people within. The dome can open and close as moments require. The dome intends to have more rigid structure elements that define a form. Still, the overall weight of the structure visually will need to feel light and to achieve this. I intend to utilize lightweight materials such as ETFE.

- How does your design address social equity and ecological sustainability?

Equity is the word of the day. Not Equality. Equality is the traditional American concept. The Declaration of Independence declares that “all men are created equal … endowed by their Creator with certain unalienable rights.” The 14th Amendment to the Constitution provides that all citizens must receive “equal protection of the laws.” In the traditional understanding, Equality means something simple and easy to implement. The protection of the rights of all individuals, along with the invasion of none of those rights.

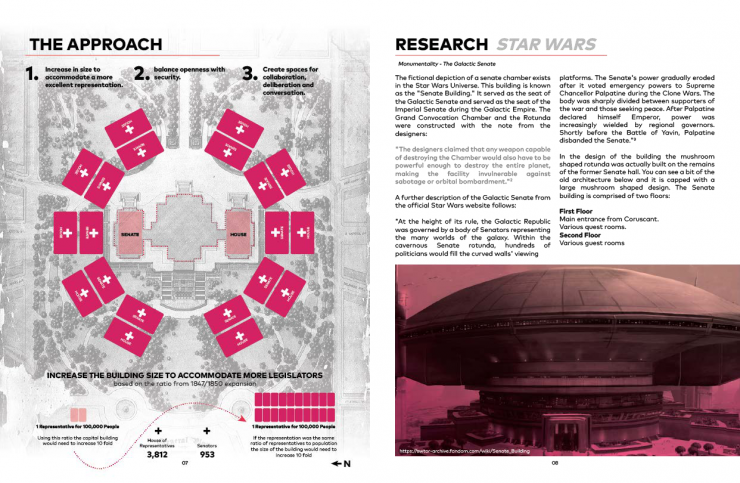

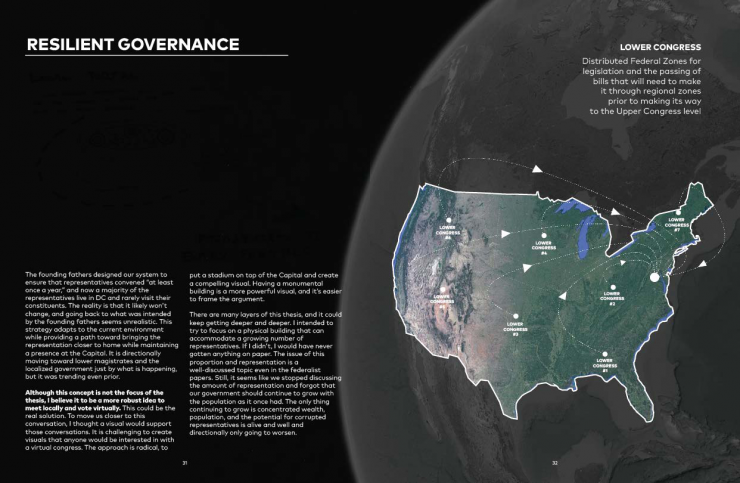

Representational equity is when two or more represented groups are standing on a relatively equal footing. To prove representational inequity, therefore, one need not show discriminatory policy. All one must show is the unequal outcome. Corporations and their lobbyist have equal access to their representatives, but the outcomes are unequal. Increasing the number of representatives is one of the tactics in improving access and reducing the concentrated interest of lobbyists.

Ecological sustainability is built into the overall redesign of the Capitol. The focus is on increasing the amount of sustainable green space, the replanting of all existing trees, and the softscape increased in scale. This will be achieved by having green roofs and removing the vehicular parking that currently exists on the site. The parking garage that will be integrated has a green roof. The Scope of Work for any construction must also adhere to ecological sustainable practices.

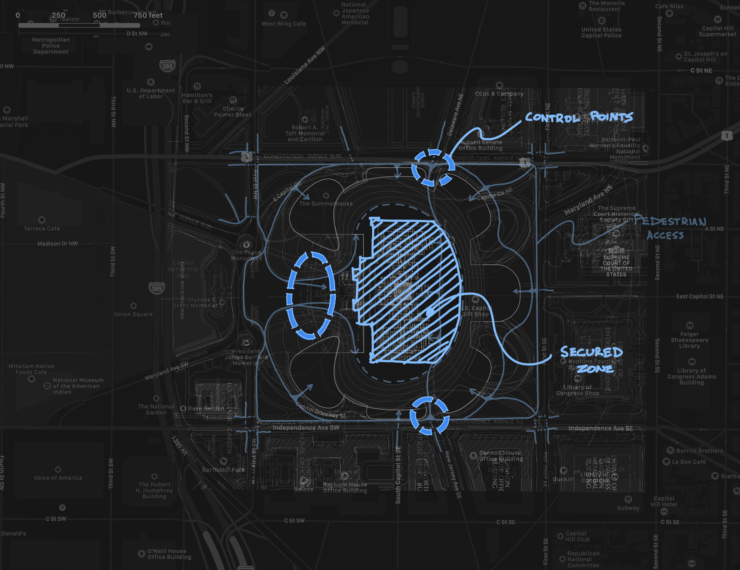

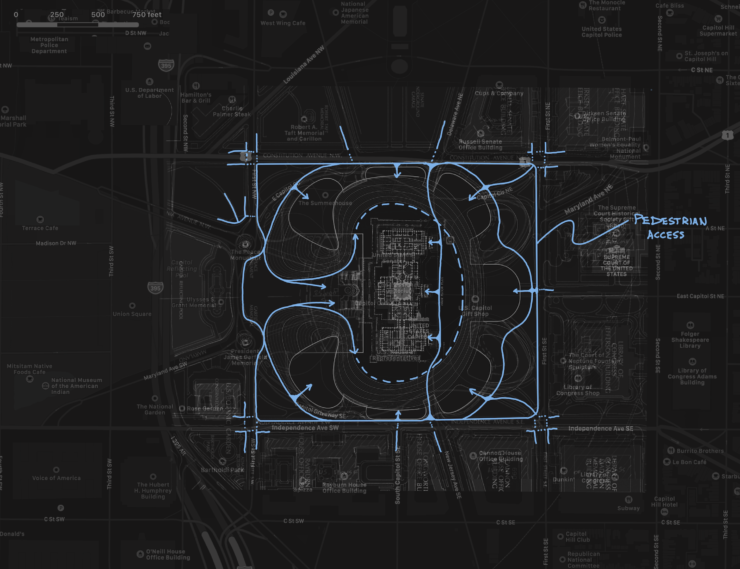

- How does the master plan, siting, building program, circulation, and massing allow accessibility and transparency?

The perimeter that builds up and defines the street wall along the perimeter on the North, East and South portions of the site will be both visually and physically transparent. The buildings will integrate softscape and create areas for conversation with the public. There is also a green ring that encircles the Federal portion of the Capitol building. This entire path is accessible to the public at both the grade portions and when it elevates into a bride that wraps around the Eastern portion of the site.

- What is the experience of the users/visitors of the building and how does that experience reinforce your thesis statement?

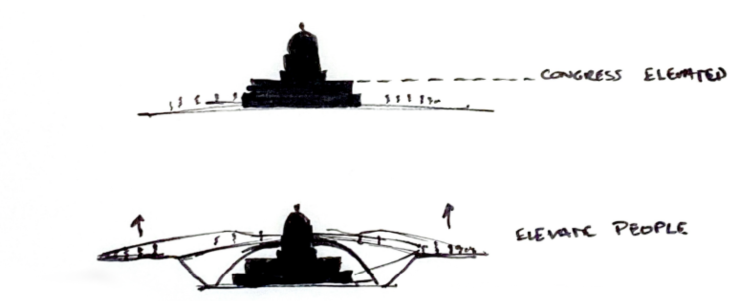

The experience of walking along the complete green path allows visitors to walk from a lower level of grade from the Capitol to its highest point which will be higher than the Speaker of the House. A primary concept is to reverse the order of hierarchy and put the People above the Government. The large arena space reinforces the growth of representation to the people and allows the Government to continue representing its people rather than special interests.

- What measures can you address to improve your building’s thermal performance, biophilia, water management, and other environmental issues?

A large dome encompassing the entire site will create a micro-climate and controlled space that can reduce the overall mechanical load and multitudes of enclosed buildings under the canopy. In my analysis, I have found that a 10% decrease in mechanical systems is possible.

This week I spent time developing one of the edges of the street a bit further. I tried to include elements to make the space more resilient and equitable. The intent was to take higher-speed traffic and to group them. I took bikes and vehicles to live in a similar space. An elevated berm would buffer the slower pedestrian traffic, and the canopy from the dome would extend over these spaces to provide respite from inclement weather. At the entryway of each perimeter building, a formal space adorned by a large tree and seating arranged side by side captures the message of Socrates’ Phaedrus teachings. I intend to refer to these openings as dialogue gates, designed to encourage the passing traffic to pause and be encouraged to chat?

In terms of the preservation, there is a sensitivity to preserving the iconic façade and form of the existing building while adding the functionality that is proposed. The green space created will take on its own identity. The space that is created between the new buildings and the existing capitol building creates a new identity of blocking out the urban fabric from views within the capitol, which will allow for the respite that is required when having conversations with any real meaning. The dome connects the entire form as one space and protects the people within. The dome can open and close as moments require. The dome intends to have more rigid structure elements that define a form. Still, the overall weight of the structure visually will need to feel light and to achieve this. I intend to utilize lightweight materials such as ETFE.

- How does your design address social equity and ecological sustainability?

Equity is the word of the day. Not Equality. Equality is the traditional American concept. The Declaration of Independence declares that “all men are created equal … endowed by their Creator with certain unalienable rights.” The 14th Amendment to the Constitution provides that all citizens must receive “equal protection of the laws.” In the traditional understanding, Equality means something simple and easy to implement. The protection of the rights of all individuals, along with the invasion of none of those rights.

Representational equity is when two or more represented groups are standing on a relatively equal footing. To prove representational inequity, therefore, one need not show discriminatory policy. All one must show is the unequal outcome. Corporations and their lobbyist have equal access to their representatives, but the outcomes are unequal. Increasing the number of representatives is one of the tactics in improving access and reducing the concentrated interest of lobbyists.

Ecological sustainability is built into the overall redesign of the Capitol. The focus is on increasing the amount of sustainable green space, the replanting of all existing trees, and the softscape increased in scale. This will be achieved by having green roofs and removing the vehicular parking that currently exists on the site. The parking garage that will be integrated has a green roof. The Scope of Work for any construction must also adhere to ecological sustainable practices.

- How does the master plan, siting, building program, circulation, and massing allow accessibility and transparency?

The perimeter that builds up and defines the street wall along the perimeter on the North, East and South portions of the site will be both visually and physically transparent. The buildings will integrate softscape and create areas for conversation with the public. There is also a green ring that encircles the Federal portion of the Capitol building. This entire path is accessible to the public at both the grade portions and when it elevates into a bride that wraps around the Eastern portion of the site.

- What is the experience of the users/visitors of the building and how does that experience reinforce your thesis statement?

The experience of walking along the complete green path allows visitors to walk from a lower level of grade from the Capitol to its highest point which will be higher than the Speaker of the House. A primary concept is to reverse the order of hierarchy and put the People above the Government. The large arena space reinforces the growth of representation to the people and allows the Government to continue representing its people rather than special interests.

- What measures can you address to improve your building’s thermal performance, biophilia, water management, and other environmental issues?

A large dome encompassing the entire site will create a micro-climate and controlled space that can reduce the overall mechanical load and multitudes of enclosed buildings under the canopy. In my analysis, I have found that a 10% decrease in mechanical systems is possible.

Review Proposal and Site/Program Development

Question 1 – What work did you do this week and what new insights did you gain from your explorations

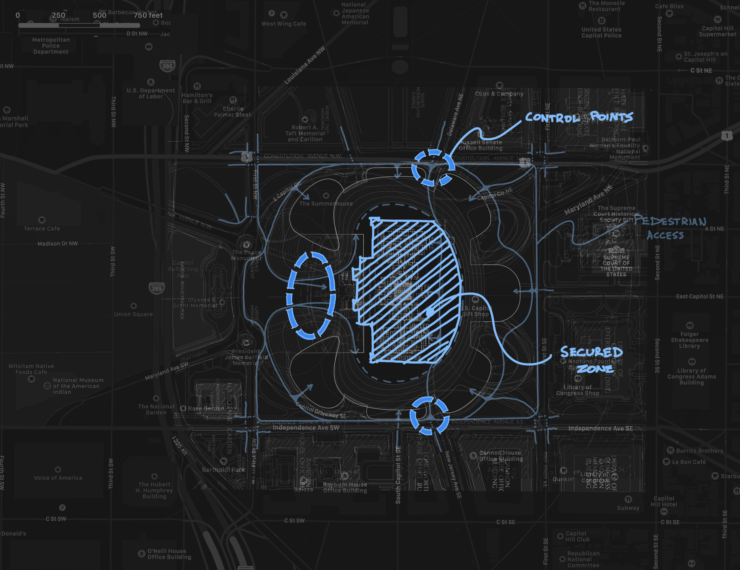

Answer 1 – This week I looked at the circulation of vehicular and pedestrians through the site. Paths of access for the public – diagramed overlays of the plan from last weeks presentation to think through the circulation of each floor.

There are other ways for the public to engage with congressional representatives and those areas are being designated as “conference” areas where conversation can happen. There are areas adjacent to their offices they can host visitors and open “protest areas” Next steps will be thinking through how the public moves through the building for a variety of purposes.

Question 2 – What was the feedback you received in the review? What parts do you agree or disagree with?

Answer 2 – A controversial and thought-provoking Thesis for sure. The conversations tended to evolve around two topics; the first is the overall form and the second is the security of the building. Below is a sampling of the comments that I received, but I have reduced the full list and focused on comments that will require a better understanding when being presented.

Comment from Karen Nelson: What do you value about the political processes of the US? What needs revision? What needs keeping? Restoring?

The immediate need is that we have taken away the diversified strategy of governance that was more local. It is common to focus on federal laws, and the media perpetuates this idea. Rather than allowing citizens within California, Massachusetts, or Florida to make their laws and decisions to govern themselves, we focus too wholly on the federal level. To battle this, we need to make it more combative, with more debate. We cannot have critical laws contingent on how one individual will vote and whether we can sway that person. That is the sign of the times when we look at one Senator and say, ” How will he vote, and it will impact all citizens. The goal would be to scale up representation (of the people and not representatives of dictators). The legislators would only pass laws that are genuinely bi-partisan and have obvious benefits to the people. If the legislators cannot agree, that means that it should not be legislated at the federal level and that the States need to take a more significant role in passing laws that would be needed to protect and promote the citizens of that State. That is the overall thinking. I need to find a way to manifest them in the overall Thesis. Right or Wrong, that is the stance that I am taking on the proposal, and I want to try to explore that further. If anything, the Thesis will cause discussion around a serious problem that we have, and I am just trying to put out into the world what I think the solution is.

Comment from Susan Morgan: be mindful of the use of terms: “preservation” has specific meaning and expectations, in distinction from rehabilitation, conservation, etc. https://www.nps.gov/tps/standards/four-treatments.htm

Yeah, this is important. Carl even mentioned this… I want to find a way to talk about it as being a problem and holding us back. Carl’s comment about preservation rules would make my proposal impossible, which is precisely the problem.

Question 3 – How do you plan to address your critiques in your work for the rest of the semester? What additional research is necessary? What design problems do you need to resolve?

Answer 3 – In order to address the comments the presentation will need to be an expanded version of what I presented. I will need to supplement the presentation with some of precedent studies that I had done last semester. This will help to justify my design decisions more precisely.

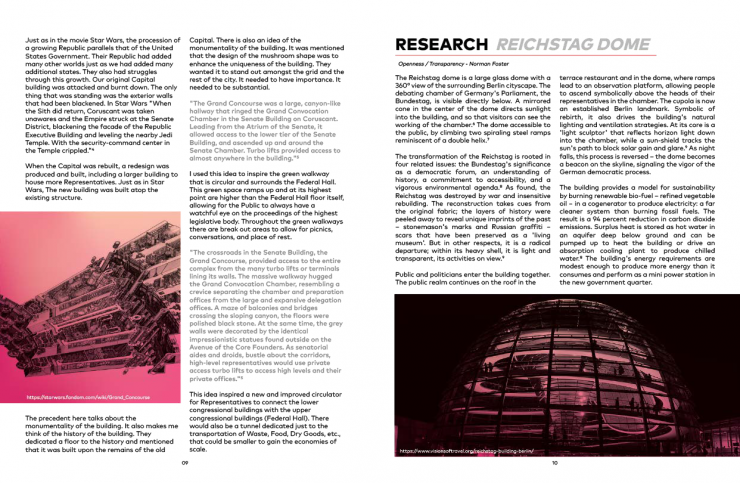

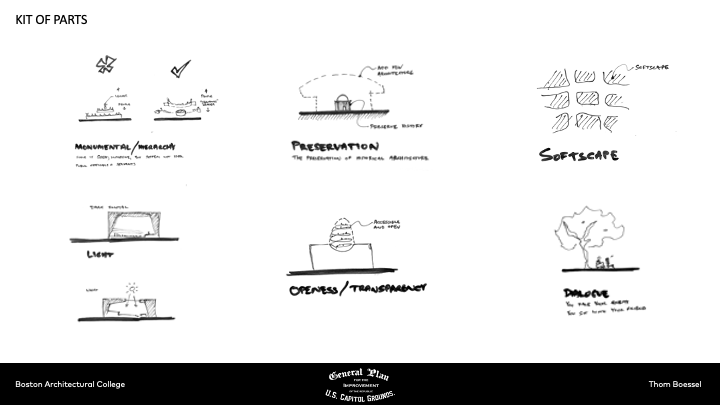

A deeper understanding of the kit of parts. For example, to know what the significance of the glass dome is.

The design problem that needs resolution is the conference areas and the overall circulation of the building. Once there is a better understanding of the circulation I can move into the form in order to more quickly get into the design documentation of the building. Part Two of this Week

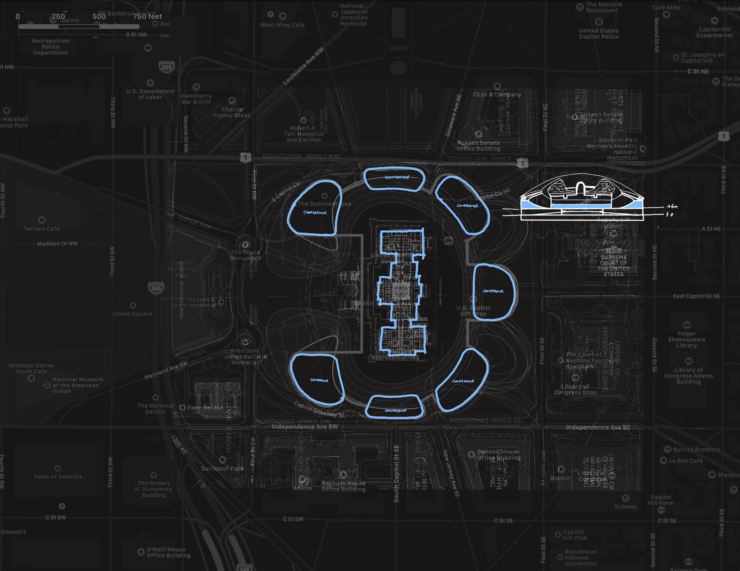

I put together a series of diagrams below. I looked at the vehicle killer access to the site as well as the pedestrian access to the site. I’ve also indicated as section with the plan highlighted boundary. This is helping me to understand the change in elevations along the length of the site.

Contemporary Interior Architecture

I have had a lifelong affinity for clean and simple lines. These designs often pop up in Finish and Japanese designs. The simplicity and rhythm of arrayed lines is so captivating to me. I selected a work by George Nakashima, because it is the foundation of most of the designs that I enjoy the most. A more rectangular form and clean lines. I have been reworking my office and these vertical lines I have been playing around with to find the right proportions before moving into the final design. I have also been playing around with stains to get the right color and sheen. George Nakashima’s form and rhythm is what is driving most of the design decisions.

My main desk is made of Walnut and differing Walnut veneers, but I have been using Ipe for my vertical pieces as the grains provide interest in depth when it is stained.

Thesis – Week 4 – Review Proposal and Site/Program Development

Paths of access for the public – diagram overlays of the plan from last weeks presentation to think through each floor.

There are other ways for the public to engage with representatives. There are “conference” areas where conversation can happen. There are areas adjacent to their offices they can host visitors and open “protest areas” Next steps will be thinking through how the public moves through the building for a variety of purposes.

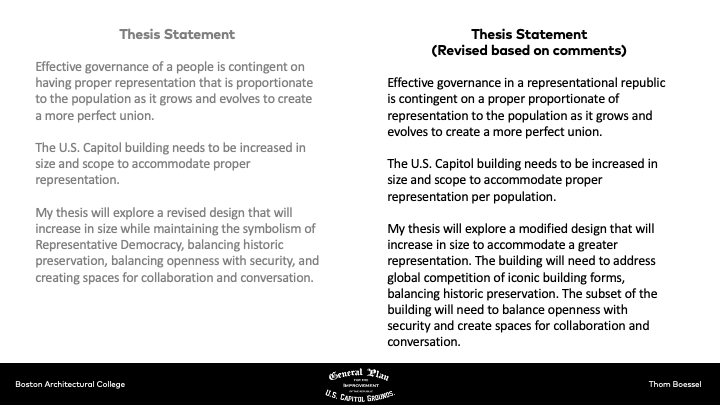

Thesis – Week 3 – Intensive

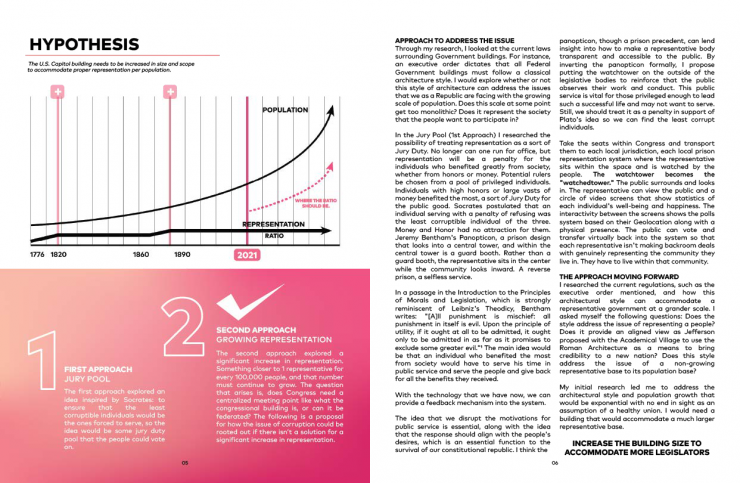

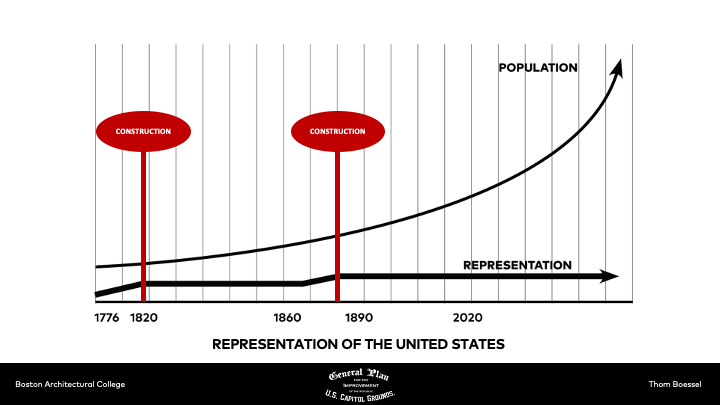

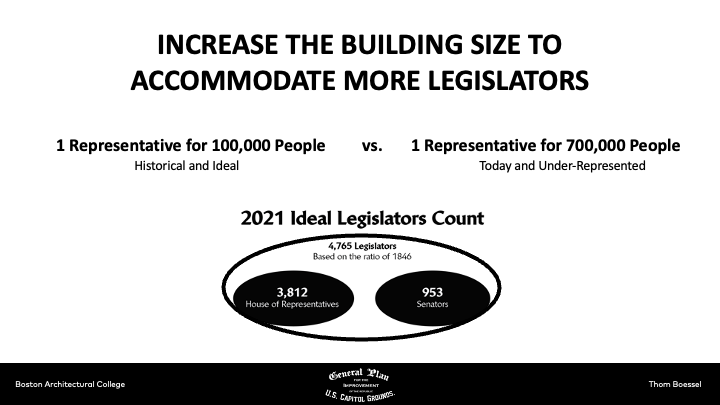

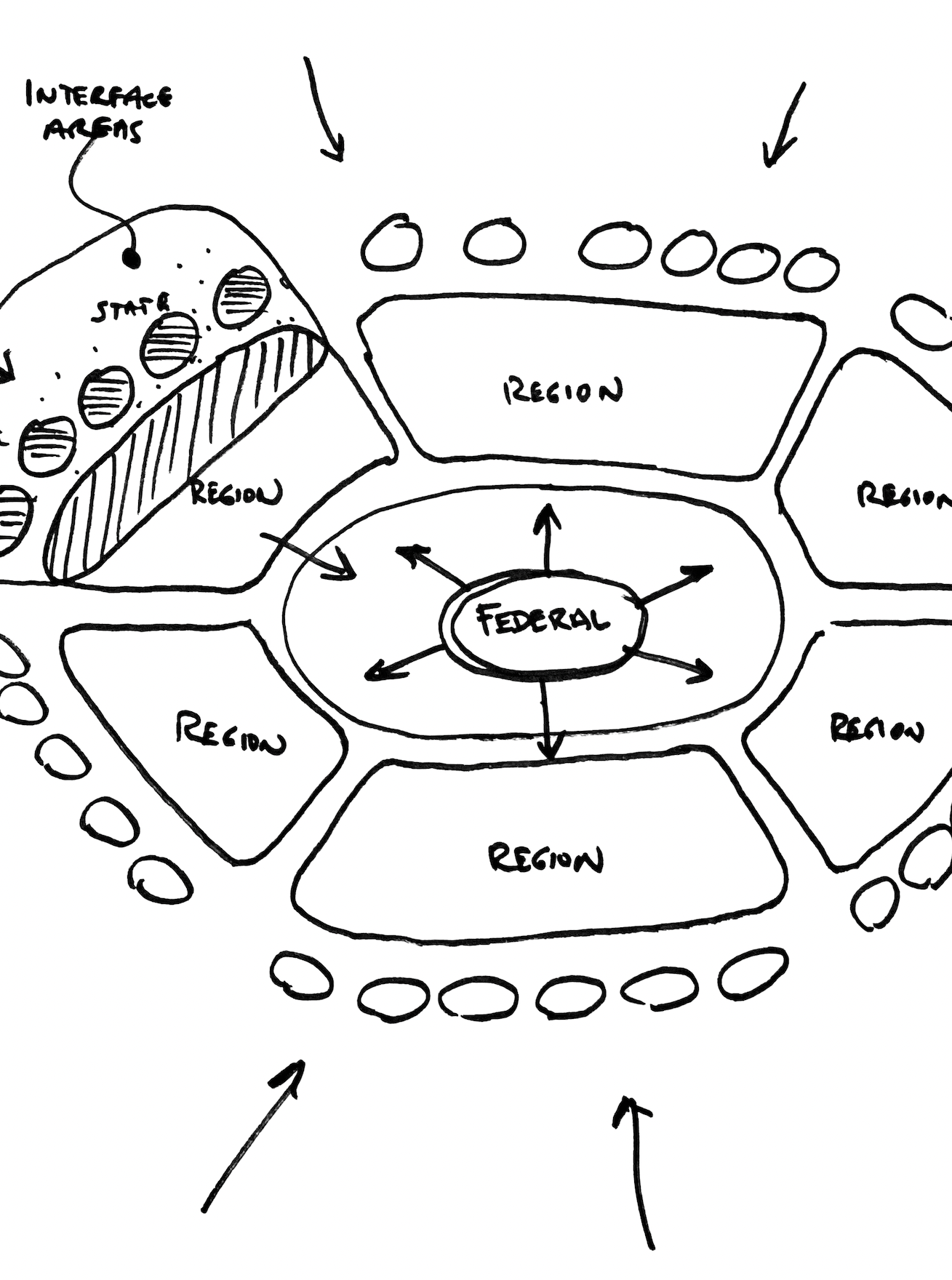

Effective governance in a representational republic is contingent on a proper proportionate of representation to the population as it grows and evolves to create a more perfect union.

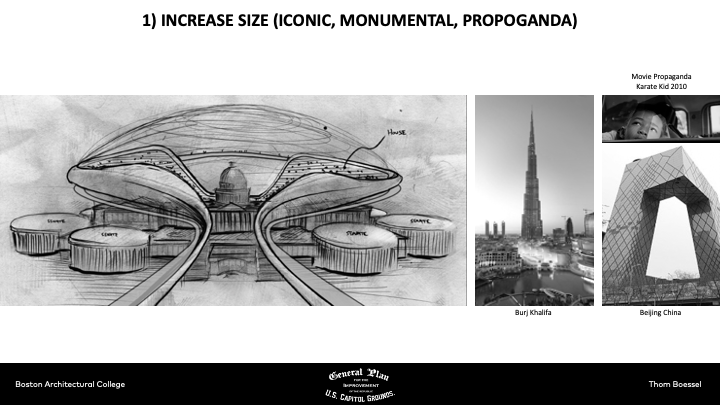

The U.S. Capitol building needs to be increased in size and scope to accommodate proper representation per population.

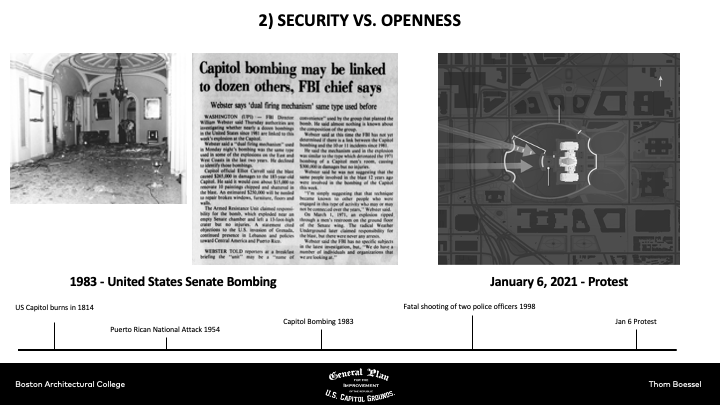

My thesis will explore a modified design that will increase in size to accommodate a greater representation. The building will need to address global competition of iconic building forms, balancing historic preservation. The subset of the building will need to balance openness with security and create spaces for collaboration and conversation.

Comments and Feedback provided During Presentation

Question from Karen Nelson: Why have representational democracy… what about direct democracy through voting directly?!

Representational democracy has shown to be the best in promoting ideas highlighted by the enlightenment. I support this approach, and history supports representational democracies. I would note that direct democracy is mob rule. We know that a large portion of the population is easily swayed and even to the point not in their long-term interest. I am a supporter of the government as a means to protect the private property of its citizens.

Comment from Karen Nelson: China has many more representatives… but not a representational democracy

The problem with their representatives is that they are not voted but placed. The more fundamental point is that they are representatives of their dictator rather than representing their constituents.

Comment from Susan Morgan: how does your approach acknowledge expectations for civic architecture, for western and US assumptions of classical architecture establishing our validity as a “young” democracy…?

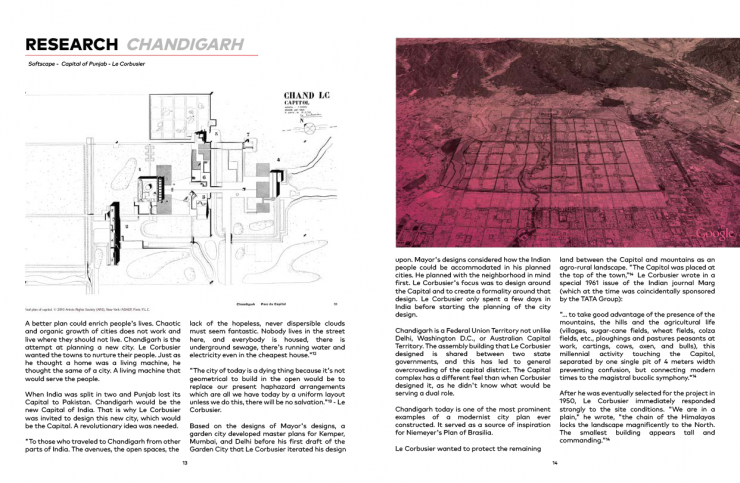

I touched on this a bit when referring to Thomas Jeffersons Academical Village in the use of Roman Architecture as a means to establish a sense of grounding the new republic in one of the greatest republics that ever existed on Earth.

Comment from Susan Morgan: be mindful of the use of terms: “preservation” has specific meaning and expectations, in distinction from rehabilitation, conservation, etc. https://www.nps.gov/tps/standards/four-treatments.htm

Yeah, this is important. Carl even mentioned this… I want to find a way to talk about it as being a problem and holding us back. Carl’s comment about preservation rules would make my proposal impossible, which is precisely the problem.

Comment from Karen Nelson: What do you value about the political processes of the US? What needs revision? What needs keeping? Restoring?

The immediate need is that we have taken away the diversified strategy of governance that was more local. It is common to focus on federal laws, and the media perpetuates this idea. Rather than allowing citizens within California, Massachusetts, or Florida to make their laws and decisions to govern themselves, we focus too wholly on the federal level. To battle this, we need to make it more combative, with more debate. We cannot have critical laws contingent on how one individual will vote and whether or not we can sway that person. That is the sign of the times when we look at one Senator and say, ” How will he vote, and it will impact all citizens. The goal would be to scale up representation (of the people and not representatives of dictators). The legislators would only pass laws that are genuinely bi-partisan and have obvious benefits to the people. If the legislators cannot agree, that means that it should not be legislated at the federal level and that the States need to take a more significant role in passing laws that would be needed to protect and promote the citizens of that State. That is the overall thinking. I need to find a way to manifest them in the overall Thesis. Right or Wrong, that is the stance that I am taking on the proposal, and I want to try to explore that further. If anything, the Thesis will cause discussion around a serious problem that we have, and I am just trying to put out into the world what I think the solution is.

Comment from Susan Morgan: Famous failed dome approach from a master of domes: https://www.historyandheadlines.com/east-st-louis-and-the-old-man-river-project/

This is some good information. Thank you for sharing.

Comment from Paul H: Is your greening of the capitol expansion symbolic of Anti-Federalist (Agrarian) versus Federalist (and Federal-Style architecture)?

I go back and forth on these two, and they exist specifically because there are different thoughts on them. I took the approach of breaking it down and its use depending on whether or not it will support the political position. For instance, the use of Agrarian, nature-oriented, would be utilized when discussions need to occur. Within the final vote, the arena of politics, the place where it becomes challenging to remove that law within that same legislative branch once it is in law. Those spaces should reflect an architecture that is bigger than man and more formal.

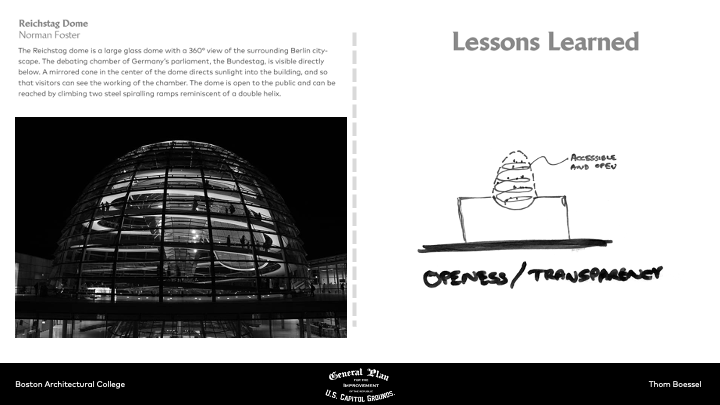

Comment from Susan Morgan: worth understanding the difference and similarities in intent and expression of Foster’s Reichstag versus his later London City Hall: https://www.fosterandpartners.com/projects/city-hall/ and http://parliamentbook.com/

Thank you. I will research this more fully.

Comment from Karen Nelson: What is the polemical argument? Heading towards fascism? Here already?

Firstly, just so we are on the same page, I rarely use the word “polemic,” I want to make sure I understand you. I understand a polemical argument as the following: A statement used in opposition or controversy of a proposition.

I don’t, or at least I am not trying to have a polemical argument, but just a pure argument. I am trying to use the facts and precedent written in our federalist papers discussing the proper proportion of representation to its citizens. The reference of this can be found in Federalist No. 58, Federalist No. 55, and there are lighter mentions of the need for it but it is just a broad statement. There is also mention of this same argument in the Federal Constitutional Convention of 1787. I could add this documentation within the Thesis as some supporting precedent.

I do not intend to make any commentary on fascism and whether it is here. The primary goal is to state that we have an issue of under representation, and that I am advocate in the foundation of this country and would like to grow representation as it has worked so well in the past.

Comment from Karen Nelson: https://www.kent.edu/magazine/shed maybe time to bury it and begin anew ontop…

I took the approach of tearing it down vs. “preserving” it depending on the hierarchy of importance. For example, the perimeter buildings that are accommodated for dialogue can be open and not as formal. Still, as legislation becomes more solidified and makes its way to the federal arena, the Architecture should formalize with that same level of importance. The area space is intended to be an architecture that is bigger than man and more formal.

Comment from Karen Nelson: What about the grounds around the capitol

The grounds around will be maintained as much as possible for occupiable green space. Any lost space will be replaced by an elevated green walk that surrounds the federal arena.

Comment from Susan Morgan: Thom: worth reviewing design thoughts about this: https://www.smithsonianmag.com/travel/winners-announced-for-national-mall-design-competition-63914108/

These are friendly spaces within the National Mall, and it reminds me of other programmed spaces like the botanical garden. When master planning, I call this type of stuff the “litter” to activate space. I feel free to use that kind of language here because the entire competition was based around the bias of “dead spaces.” I wonder if a landscape architect intentionally designed an open space for a particular reason, and others call it “dead space.” I am sure. However, I am an advocate for activating spaces like this with skating rinks, fountains, etc.

Comment from Karen Nelson: Are we under-represented? Really>

Yes, we are under-represented; a school board is much more accessible than a house of representatives and even more so than a senator. Scarcity value is a good analogy for this.

Comment from Susan Morgan: Thom and also: https://www.architectmagazine.com/design/memorials-for-the-future-finalists-revealed_o

I need to get on your newsletter! You have a ton of great resources. There is a moment within the building, the house, and the senate chambers that would be converted into a museum space, and I was struggling with what to do with it that wasn’t just locking it in time but making it a more interactive learning experience, and this competition has some great thinking along that line already. Thank you for sharing.

Comment from Karen Nelson: How many people can function?

I alluded to this in my previous response, but the question I am trying to solve has a different importance threshold. When we talk about functioning, yes, it will function. If the key performance metrics are evaluated by whether bills get passed, I am trying to fix that evaluation. We need a new standard for the key performance metrics. The standard should become something similar to “did the bills that get passed have a positive benefit to the people and did a majority agree?” Too often, we pass bills by the margin of a single person, and this is a recent legislative change that we call the “nuclear option.” We can easily say, well, that is the solution to get rid of the nuclear option. That is a solution and should happen, but we also need to address a growing population and wealth to representation that is not growing. It is an obvious problem, and my proposal is to have more representation to fend off the influence of potential corruption.

Read moreThesis – Week 2 – Pecha Kucha

Karen Nelson Comments

- Q1. Provocative spatial and political argument

- A1. Thank you.

- Q2. Maintain only an image of representational democracy?!

- A2. This is my nod to the embedded corrupt nature of a system with a locked representation while we can have our first trillionaire and how a small handful can manipulate a small group (non growing representatives). The corruption will only become worse… There are other solutions, but I am trying to maintain the form of an idealistic form of what it should be rather than the reality of the situation

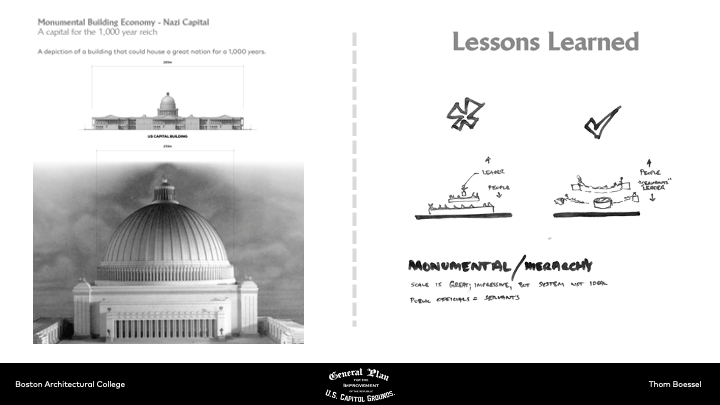

- Q3. How do you make decisions about the form of the project? How serious… how sci-fi? Is it worth contrasting our numbers to those of China and its larger legislature?

- A3. I have a precedent I am using within my research about the Galactic Senate in Star Wars, which is about the monumentality. I am also using the Nazi Capital as a precedent for the propaganda piece and that is when I relate it to China. A representative republic needs to have an answer, so it doesn’t get left behind, and can continue to be relevant. I like to make a comparison of the church using the best “artists” like Michelangelo to showcase. The best of the best was used as an association. This is similar to Celebrities, Athletes, Institutions, etc. They use the best of the arts to illustrate their propaganda to get an association bump. It is important to have a form that reflects that in order to compete against authoritarian governments. We don’t want the next generation of surface thinking to be “China is cool” and “America is dead”

Daniel Daou Comments

- Q1. Concur, very provocative. But the symbolic dimension needs to be foregrounded. the driving argument can’t be a merely functional one.

- A1. I have a precedent of the nazi capital, which its intent was to create a monumental space that would be a symbol of power. The goal was to have delegates that arrive to brag about the architecture back home. This happens a lot in China and UAE, and it has very valid societal impacts just by being a symbol (propoganda). There are overlaps of China (Communism) and their use of propaganda and how a representational democracy can combat that propaganda without feeling left behind.

- Q2. What would the “terms of criticism” be?

- The terms of criticism are as follows: 1) Is there a space to meet with representatives in a more direct and neutral way? The intent of the space would be to acknowledge that both parties; that of the representative and the citizen, are equal and there is not hierarchy above one another in these dialogue zones to better understand the needs of the community. 2) When the representatives are working, can the public see them? 3) Is there space for the public at hearings, committees, office meetings, and when congress is in session? 4) Does the building meet the standards of a healthy working atmosphere (healthy building)? 5) Does the building have a monumental stance in its environment that can command attention?

- Q3. How do you evaluate how successful your design/research is? Does anything go? Speculation is perfectly fine, but internal narrative self-consistency becomes paramount.

- A3. On the surface it is speculation, and hopefully the supporting documentation can support my Key Performance Index, which is: 1) Increase the Size. 2) Balance of Security and Openness. 3) Creating spaces for Collaboration and Conversation. 4) Creation of regional zones of lesser magistrates that will have a standard operating procedure of judgement in order to pass any potential legislation on to the Federal Senate and House for a vote.

Susan Morgan Comments

- Q1. worth including in an intro why we should keep/add on to the existing capitol building versus step away and create new, adaptable facility for proper representation. Side note: in the world of digital meeting, to what extent is the assumption of physical presence appropriate for the next 50+ years?

- A1. Great point on a focus on the keep/add of existing capital vs new. I explored this idea early on and there is some interest in exploring it further, but it tended to not be manifesting itself in form, but rather a cerebral push and pull about the proper way of representation when it intersects technology. I can get carried away with this idea, because it is rich.

- Q2. With such direct visual comparisons to Buckminster Fuller and Norman Foster, you should be explicit about these references and acknowledge their relationship to assumptions and visions for the physical expression of political engagement.

- A2. Understood. I do have these references in the expanded version of the presentation, but I will ensure that I make reference within a reduced presentation as well.

Ekaterina Siemoneit Comments

- Q1. Some sketches reminds me of Reichstag glass dome by Norman Foster. Was it your inspiration?

- A1. Yes I did look at this building. It is very beautiful. I also looked at some concepts for the Tokyo Stadiums that have a wrapping path around the building. Very good catch!

Molly Boudreau Comments

- Q1. Seems costly. Maybe they should all remote work instead? Ha!

- A1. I understand you are being playful, but I think we both know this could be a reality very easily, and I touch on it slightly, but don’t go too much into it because of my bias towards built form.

Ryan Hoppe Comments

- Q1. What security considerations have you made about having a public elevated platform above a house of government given what we saw in January?

- A1. I intend to touch on the full history of attacks on the Capitol. I specifically touch on “1983 U.S. Senate bombing” by the New Communist Movement. I am focused on the fortification from weaponry and bombs along with cordining of populations.

Thesis – Week 1 – Revisiting and Expanding

Thesis Overview

The topic explores the governance of a civilization by the people and how to develop the least corruptible form of government, and how Architecture plays a role. History and recognition that some government Architecture begins to outdate and restrict the people. How can Architecture redefine the relationship between its representation and the people it represents? This topic is vital to all our civilization as there is a built constraint of the bruilt form. Still, it lives in a world where the monetary, corporate interests, and political beliefs are ever-changing and growing.

Thesis Statement

- The issue I am addressing: Effective governance of a people is contingent on having proper representation that is proportionate to the population as it grows and evolves to create a more perfect union.

- Hypothesis for how the issue can be addressed through design, as specifically as possible; and The U.S. Capitol building needs to be increased in size in order to follow the same trend line of representation to population. The Capitol building has stopped its growth, but the population has continued to increase in size. To design a building that can accommodate the current representative needs spatially and how it can continue to grow with our population. Create additional program to accommodate intimate and group conversations with the representatives.

- The program, site, and other information you propose to use as a test of your hypothesis. Design vignettes of the programmatic spaces as a comparison and illustrate the improved scenario.

Kit of Parts

Preservation – The preservation of a social contract

Preservation – The preservation of historical architecture

Monumentality – Impressive scale; to inspire; to bring attention to

Hierarchy – Public officials should be physically lower, vulnerable to the public

Light – Natural light to enter the space and provide a stronger connection with the outside

Openness – Physically and Virtually more accessible to the public

Transparency – Meeting logs, conversations, emails, available openly without FOIA.

Softscape – Landscape areas for conversation in a “natural” environment.

Dialogue – You face your enemy; you sit with your friend. Changing the way we sit with our representation.

The Watchtower becomes the Watchedtower.

Terms of Criticism

Is there a space to meet with representatives in a more natural way?

When the representatives are working, can the public see them?

Is there space for the public at hearings, committees, office meetings, and when congress is in session?

Does the building meet the standards of a healthy working atmosphere (healthy building)?

Does the building have a monumental stance in its environment that can command attention?

Design Directions

A monumental building that commands attention and open to the public. A Grand scale that can accommodate public viewing and all representatives with future growth.

A lesser magistrate models. Abandon the capital building and rebuild state capitals to draw attention to the strength within the state and to make them more accessible locally.

A focus on security and accessibility – Design a building that is resilient to not just future climate change but to a populace that needs to balance the security and safety of the public as well as the accessibility of the public.

Research

The Doctrine of the Lesser Magistrates – Matthew J. Trewhella

Site Selection

The site still makes sense. I have a drive to complete the thesis as started. The foundation is strong and there are moments that need to be defined and those placemaking situations will require more research in order to have some key performance indices for whether or not they are successful or not.

What is the Thesis

The primary objective of a thesis statement is to be that constant reminder of what the topic is. This helps to ensure that we don’t go off topic and keep the focus on the initial system. For instance, I was asking a research question of what are the factors that lead to society to circulate large scale buildings and bring attention to it. Monumentality plays a big role and in the Nazi capital it was purposeful to bring attention to the grandeur of the place and their society, so others who would visit would “write home about it.” The kit of parts are the moments of the placemaking that can define the spaces within the overarching building that will support the openness, transparency, and accessibility of the building.

Update August 15

Terms of Criticism (Revised)

Is there a space to meet with representatives in a more direct and neutral way? The intent of the space would be to acknowledge that both parties; that of the representative and the citizen, are equal and there is not hierarchy above one another in these dialogue zones to better understand the needs of the community.

When the representatives are working, can the public see them?

Is there space for the public at hearings, committees, office meetings, and when congress is in session?

Does the building meet the standards of a healthy working atmosphere (healthy building)?

Does the building have a monumental stance in its environment that can command attention?

For the design direction, I’d stick with the Capitol, but I do like the idea of also pursuing smaller buildings too. Perhaps the design direction you go in has a large building, but then also has smaller buildings spread out with passageways between them – where people from different parts of the country work. That way, you’d balance accessibility with the ability to close off paths – and focus on smaller representative groups collaborating together before bringing legislation to the larger group.

I really like this idea. There might be a Standard Operating Procedure that associates with these smaller rooms. I am thinking simple rules and if it makes it past the smaller committees then it can be presented to the larger federal level.

1) Delete existing laws/regulations… For every bill proposed a proposal of revision or dissolution of an existing law/regulation must accompany it. 2) Parties Involved… Who does this benefit?3) Impact of existing state laws (other states than the repesentative)… How many State laws will this proposed bill impact negatively/positively. Is this law in opposition of State Laws? Is this law in support of existing State Laws?

It would be interesting to explore what those spaces could look like architecturally.

I think this is an important step to a Representative Democracy is having a system to deal with any new proposals to check against itself. We often make so many laws that are contrary to other states and even existing laws. The Legislators tend to pass this off on the Judicial system to resolve the conflict, and it perpetuates the idea that the Judicial system is making law, while the onus is on the Legislators, but they don’t have a system like this to check against. It would be a great idea to explore what those spaces and interactions look like architecturally. I have diagramed these relationships below. Showing how the people can interact within a space with regions and states and then those regions will be able to check against themselves before moving to the floor of the federal legislators. This is necessary in my design because there is such a strong Federal power that it needs multiple checks before arriving.

The Salvage of Abu Simb

by LUCIA ALLAIS

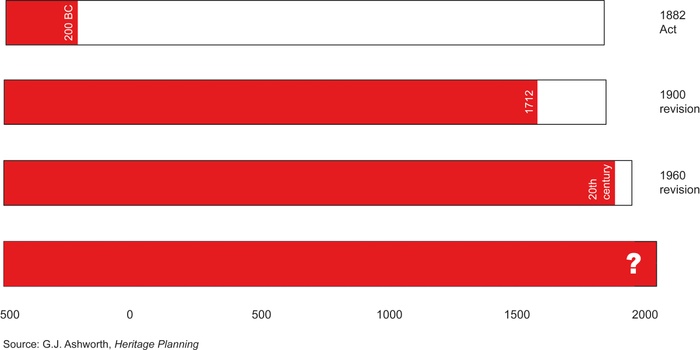

In 1965, British architectural historian and technology enthusiast Reyner Banham wrote a letter to a preservationist who had asked him to intervene against the demolition of the Reliance Building in Chicago. “The day you find me speaking up for the preservation of any building whatsoever,” Banham wrote, “send flowers, the next stage will be the general paralysis of the insane.” Banham refused to engage in what he called “idiotic preservationist panics” for fear of being subjected to similar requests from “every crackpot period group and broken-down country-house owner in England.” But he could also have aimed his sarcasm at preservationists with much more cos mopolitan tastes. In 1965, after all, Le Corbusier’s Villa Savoye was declared a national historic monument in France, thanks in part to an international advocacy campaign by modernist architects and historians, including Siegfried Giedion. The mid-1960s constitutes something of a historical turn ing point, when a wave of fervor swept up architects and architectural histo rians of every allegiance across Europe and North America, and transformed architectural preservation from a fringe movement into a mainstream political cause. A few dates serve to evidence this shift. In 1963, architects (including Philip Johnson) joined urban activists (including Jane Jacobs) to protest the demolition of New York’s Penn Station. In 1964, a group of architects and archaeologists from sixteen countries coauthored the Venice Charter, the first international document to call for the protection of both monuments and historic sites. At the 1965 White House conference where the phrase “world heritage” was coined, visionaries R. Buckminster Fuller and John McHale joined architectural historian Vincent Scully to recommend that “the cultural diversity of the earth” be conserved as a resource, akin to oil or gas. This three-year period is bracketed by major acts of legislation that extended the legal protection of historic buildings to entire urban districts: the 1962 Loi Malraux in France and the 1966 National Historic Preservation Act in the United States. In 1972, the World Heritage Convention was signed by the United Nations’ cultural agency, Unesco, establishing mechanisms for protecting sites of natural and cultural heritage worldwide.

So where Banham saw “idiotic panics,” others saw political empowerment. The timeline I have sketched out is rapidly being historicized as the start of a dramatic rise in the political power of preservationists, coincident with a global shift from conserving individual monuments to preserving entire environments. According to this new historiography, the 1960s saw an enlarge ment of preservation’s domain and a concurrent expansion of its political effectiveness worldwide. The preservationist Alan Powers even identifies 1965-1985 as a “heroic period of conservation,” when the “parallel progress of voluntary association and legislative and administrative action, combined with media pressure,” triggered a politics of expansion that aimed to establish “the place of conservation in life as a whole.” Powers’s use of the preferred British term conservation gives away his geographic specificity. But like many other national narratives, his story has international implications, whereby local “heroism” helped to ignite a global movement, which, in turn, followed the political example of national groups to bring pressure onto international organizations. Thus, in an accumulating number of national histories, the globalization of preservation politics is ascribed to a convergence of political will along four axes: an alliance between modern architects and historic preservationists; a shift of media attention from object-buildings to urban ensembles and vernacular milieus; a joining of forces between nature conservationists and architectural activists; and a concerted effort by scholars to diversify the architectural canon and the demand for its protection. And so (the narrative goes) the protective boundary of preservation was progressively enlarged, by sheer force of activism, to include ever-larger sectors of the built environment.

The trouble with this narrative of progressive enlargement lies in its conception of architectural history; specifically, the notion that architectural monuments stayed the same while around them mentalities changed. If a new politics of expansion arose from a synchronous wave of activist practices, how was this politics enacted at the architectural scale? What values and criteria had to be invented for historic architecture to sustain its expanded political charge? Perhaps most importantly, how did preservation, once conceived as a historical accumulation of buildings in time, become a spatial practice that lays a claim to entire environments?

Some historians have pointed to the social, legal, and technological forms of mediation that intervened to accomplish this enlargement. In the 1970s, the German art historian Willibald Sauerländer commented on the growing consensus that an “extension of heritage” had occurred, but he expressed skepticism that the process had been purely additive. “To conserve is not only to preserve historical evidence but also to mediate it,” he wrote. Instead he hypothesized a shift from quantity to quality—from art-historical “accumulation” to a populist “cult of monuments”—and hinted that public demand for expanding the boundary of protection did not necessarily empower the people who found themselves inside that boundary. International activists tracking this expansion on the global stage soon detected another layer of mediation, pointing out that case-by-case activism had been accompanied by a dissemination of norms. Piero Gazzola, founder of the International Council on Monuments and Sites (ICOMOS, the first nongovernmental organization devoted to architecture), remarked that preservationists turned their attention to urban spaces and vernacular typologies all over the world at the same time. “In the span of ten years,” he wrote in 1978, “we have gone from punctual protection to global protection.” But he also warned against thinking that this “diffusion of criteria” had created a blanket of control. “Total protection,” he wrote, “can lead to non-protection.”

Over the next two decades, talk of heritage expansion turned to concern for heritage inflation. The French historian Françoise Choay, for instance, concluded her authoritative 1992 history of patrimony with a chapter on new technologies—of mass communication and transportation—which she blamed for turning heritage into an instrument of “hidden mediation” that fueled a “cult of passive self-contemplation” worldwide. Appealing to Sigmund Freud, she detected in the diffuse globalization of heritage a strain of narcissism. “Heritage today,” she wrote, “seems to play the role of a vast mirror in which we . . . contemplate our own image.” More recently, the architect Rem Koolhaas has analyzed what he calls “the onward march of preservation” and confirmed Choay’s diagnosis of passivity, concluding that “preservation is overtaking us.” In this formulation, preservation is a spatiotemporal mechanism that compresses historical values and disseminates them in order to control the built environment.

Together, Sauerländer, Gazzola, Choay, and Koolhaas provide the seeds for a critique of the heroic narrative of preservation history because they point out that the expansion of preservation has been accompanied by a fundamental shift in how historical and political agency operate through architecture. If historic preservation entered a new phase in the mid-1960s, it did so not only because preservationists acquired more political power but because power found new ways to circulate through the built environment. Architectural agency took on new norms, new forms, new techniques.

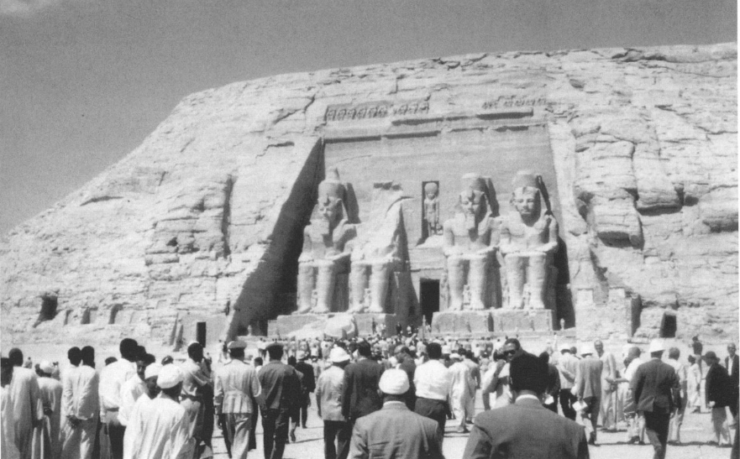

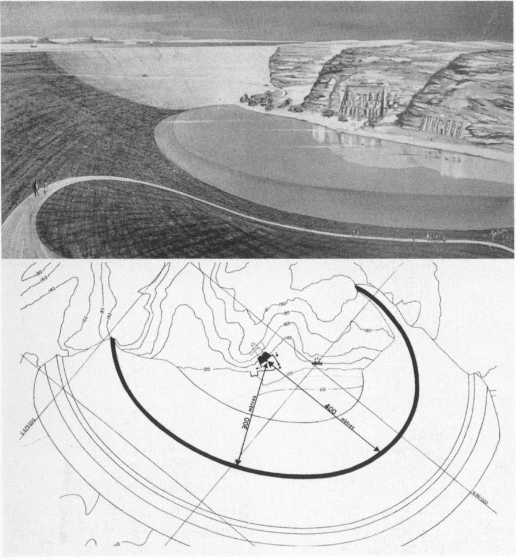

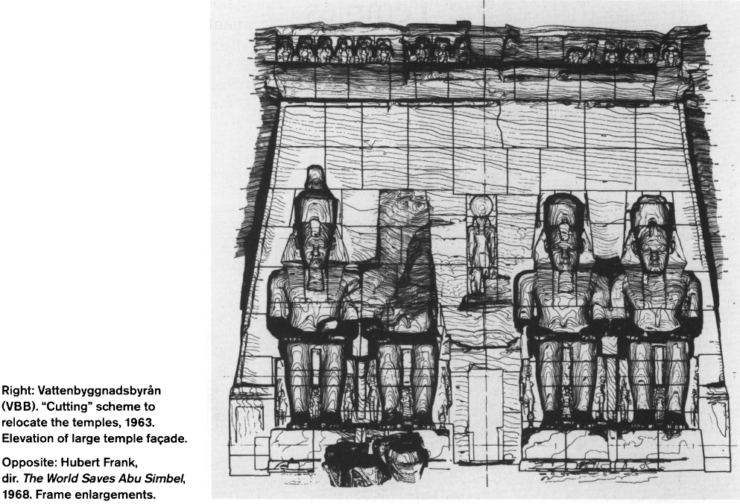

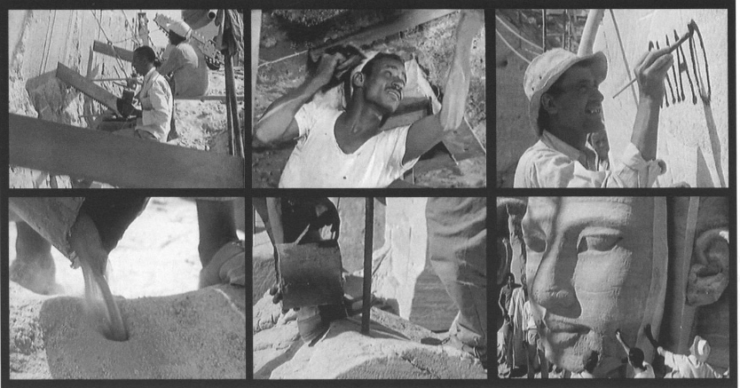

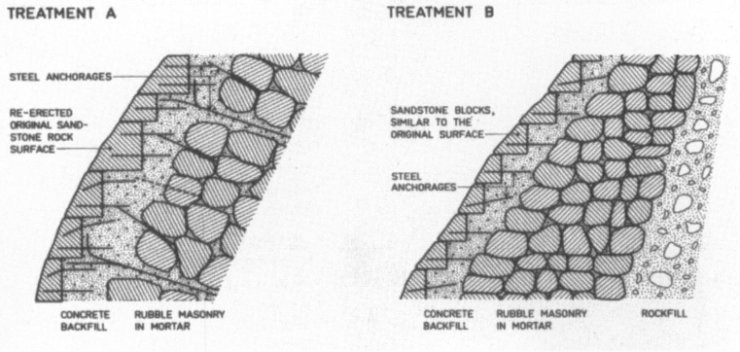

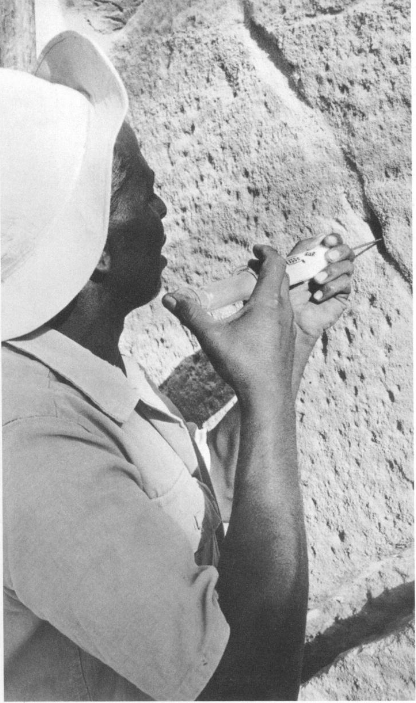

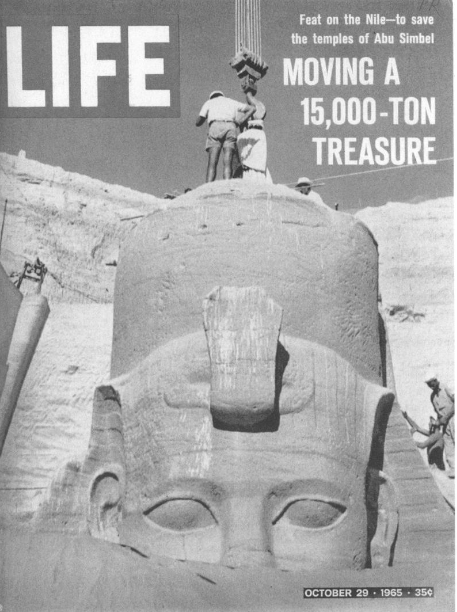

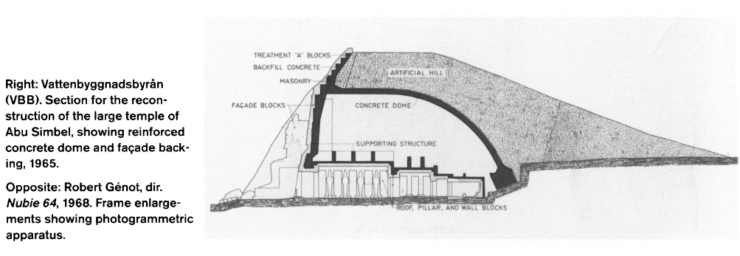

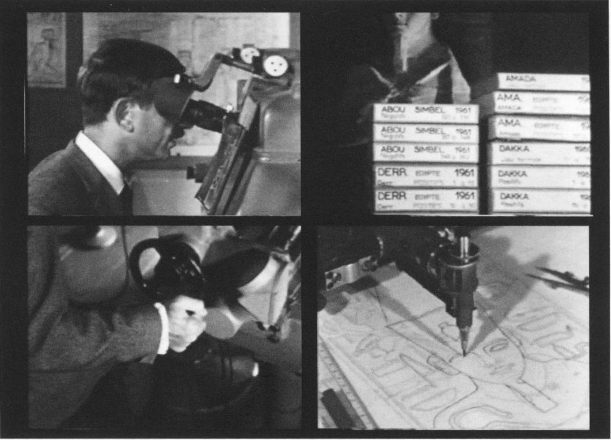

This article addresses the radical change that occurred in preservation’s modus operandi beginning in the mid-1960s by telling the story of one episode when the expansion of preservation’s domain “from the punctual to the global” was the subject of an international engineering competition. The objects of the competition were the temples of Abu Simbel: two massive pharaonic shrines, fronted by eight colossal figures that were carved out of a sandstone cliff on the banks of the Nile during the rule of Rameses II in the twelfth century BCE. From 1960 to 1968, the temple complex was saved from drowning, moved 208 meters over and 65 meters up from its original site in a highly publicized international campaign led by Unesco. The salvage remains a world-historical event and an important marker in the history of preservation. The monuments were so large and monolithic that they blurred the boundaries between an architectural object and its site, and their salvage was part of a regional plan that exemplified preservation’s expanded scale of operation. Furthermore, because the temples were so remote and had no “local” constituency advocating on their behalf, the question of what kind of technical and political mediation was required for their salvage was brought into particular relief.10 They also offer a unique case study of the role technology has played in making historic preservation a global field of expertise. The salvage of Abu Simbel exemplifies the new model of monumentality that was catalyzed when new approaches to preservation mixed with geopoliti cal ambitions and experimental engineering.

In this article I focus on technology not only because the international preservation movement coalesced in reaction to a perceived acceleration of technological progress—although it is true that the proliferation of public works and engineering projects throughout the 1960s served as a rallying cry for both environmental and architectural activists. Nor is it simply that technological obsolescence became, in this period, the dominant criterion for determining what qualifies as historic architecture to be preserved— although many of the buildings that turned modernists into preservationists, such as Penn Station and the Euston Arch, had been built around industrial technologies, now newly old.11 More generally, architects’ attitudes toward technology were crucial in determining where they stood in the debates about the historical self-image of modernism and the fate of its most famous buildings. No doubt Banham’s real objection to preservation was technological: for him, to be modern was “to keep pace with a technological situation,” not to conserve and memorialize past architectural technologies.12 Yet, like many other architectural practitioners during this period, preservationists tried to “keep pace” with history by adopting and adapting the technologies against which they were fighting. I focus on technology, then, because chang ing conceptions of history, including architectural history, must be thought in relation to changing technologies, particularly those building technologies that translated notions of historical progress, of development, of teleology— of time—into space.

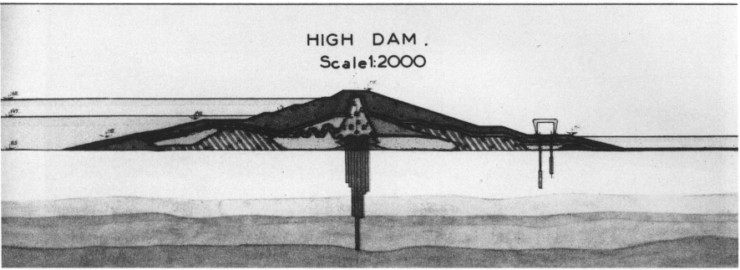

Monument and/as Infrastructure

On May 14, 1964, the New York Times published a photograph of Soviet president Nikita Khrushchev and Egyptian president Gamal Abdel Nasser “hurling rocks” into the Nile to inaugurate the construction of the Aswan High Dam. Originally designed in 1946 by an international consortium led by a German-American engineer, the dam was to be one of the largest rock fill dams ever built, its size commensurate with its impressive multipurpose task: to retain water in a gigantic reservoir lake, generating enough energy to electrify the Nile Valley all the way to the delta and permanently irrigate much of Egypt along the way. The dam was also to become the object of an intense and prolonged geopolitical tug-of-war. As soon as Nasser came to power in 1952, he made the project central to his plan for jump-starting the country’s development and achieving agricultural self-sufficiency. Large infrastructural projects were frequently used by nonaligned leaders like Nasser to leverage their strategic position with both sides of the Cold War’s East-West divide, and in 1956 Nasser approached the West, receiving an immediate offer to fund the dam from the World Bank, the United States, and the United Kingdom. But after realizing that this economic debt would not dictate Egypt’s political allegiance, the Western consortium withdrew its offer. Defiant, Nasser nationalized the Suez Canal to raise funds for the dam— sparking a crisis that would shake up the Middle East for decades—and turned to the Eastern bloc for further support. By 1964, the dam was being built largely with Soviet money and expertise.13 In this context, Khrushchev and Nasser’s act of “hurling rocks” stands out as a raw and triumphant demonstration of technopolitics: a delegation, by sheer force of gravity, of an immense amount of political power to an enormous machine.

The inaugural photograph was disseminated in the West as a cautionary tale. Suspended in midair, the stones of the Aswan High Dam were carriers of a political force that could divert not only the flow of the Nile but also Western channels of influence in the Middle East. There was no shortage of infrastructural metaphors to make the point: Khrushchev used his Egyptian trip to declare his intentions to “drown capitalism on the African continent,” and another photo opportunity the next day showed the leaders pushing a button, in unison, to detonate the first explosion that would demolish temporary construction digs. Western com mentators witnessing this political theater responded by attacking the monumental qualities of the dam, calling it “Nasser’s pyramid” and an “Egyptian monopolization of the Nile.”14 Not to be outdone in monumental rhetoric, Nasser’s Ministry of Information spent much of the early 1960s comparing the Aswan High Dam to the monuments of pharaonic Egypt. One pamphlet, aptly titled “Aswan: The City with Public Works More Grandiose Than Obelisks and Pyramids,” computed that the dam would require “enough stone to build 26 ancient pyramids,” a comparison made easier by the fact that the dam was itself “in the form of a collapsed pyra mid.”15 But the ministry also emphasized the dam’s absolute modernity. Whereas the pyramids were “monstrous architectural conceptions” that had wasted material and exploited labor for the memory of only a “few powerful men,” the Aswan High Dam was a new kind of monument, “larger and more human” because it would remain active, in the service of all Egyptians, in hydrological perpetuity.16

The contest between two kinds of monumentality (the one ancient and static, the other modern and dynamic) was no mere metaphor. The six-trillion cubic-foot lake created by the dam was projected to flood dozens of ancient temples and archaeological sites in Nubia that sat along the banks of the Nile. By 1964 the dam had become a veritable iron curtain neatly dividing the Nile Valley between Eastern and Western blocks, each side running a large scale engineering project. Downstream, more than 800 Russian engineers built the dam and its associated power stations. Upstream, Nubia was crowded with Western archaeologists and engineers brought by Unesco to survey and salvage hundreds of monuments and sites.

The temples of Abu Simbel were the largest and most impressive of the temples, and they were understood from the start of the project as counter monuments to the dam. Like the dam, they represented engineering projects of massive scale. Also like the dam, their salvage would require unprecedented international cooperation. But unlike the dam, which gen era ted power, the colossi of Abu Simbel appeared to absorb the immense effort that was invested in them. For instance, in 1960, Unesco publicized its appeal to “Save the Treasures of Nubia” on the cover of the Courier with an image of the tem ples sitting impassibly, facing the Nile. Four years later, the temples appeared again on a Courier cover, which proclaimed this time that “Victory in Nubia” had been achieved.17 Nowhere was the human agency required to achieve this victory in evidence: the temples sat unchanged, still facing the Nile impassibly. In contrast, Soviet publications commemorating Khrushchev’s visit to Aswan depicted hydroelectricity as a source of political empowerment, proudly claiming that “Russian-Egyptian friendship” had built the dam. Against this political specificity, Unesco made use of what Bruno Latour has called its “sociological Esperanto” to describe the work of preservation: according to the organization’s publicity material, “the world saved Abu Simbel.”18

What does this mean? One place to start decoding Unesco’s abstract language is the final engineering report for the salvage of the temples, whose preface breaks down “the world” into six collective nouns:

The EGYPTIAN PEOPLE, through their GOVERNMENT, have shoul dered the greatest part of the burden of this noble enterprise.

UNESCO called on nations and people all over the world and urged them to make generous contributions.

The ARCHAEOLOGIST, represented by specialists from Egypt as well as from other countries, outlined the fundamental conditions for the Salvage Operation.

The CONTRACTOR, in the form of a Joint Venture composed of companies from Egypt, Italy, France, Germany and Sweden, executed the gigantic works involved.

The CONSULTING ENGINEER planned and prepared the whole project and supervised the works. He also submitted this Report.19

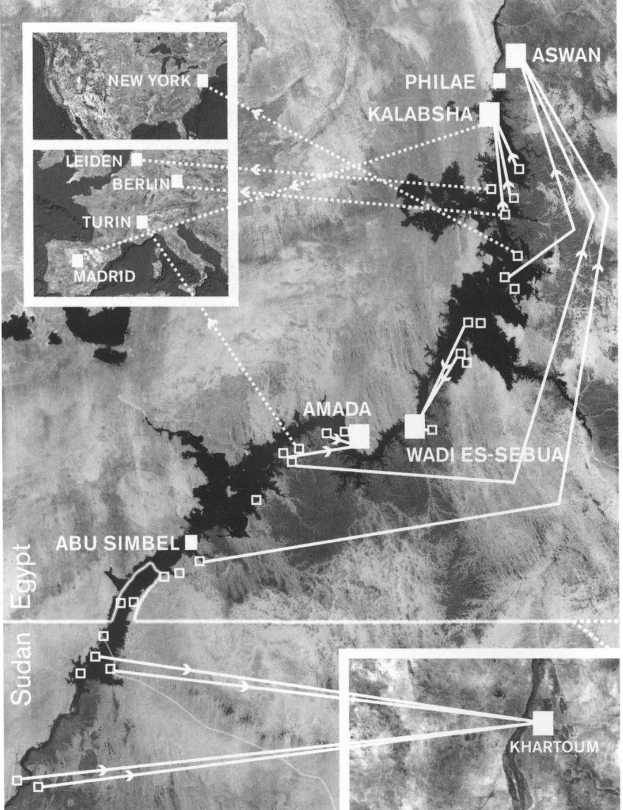

This disembodied chain of human agency actually describes a specific set of actors who participated not only in saving Abu Simbel but also in the entire campaign to salvage the twenty-four other temples of Nubia. Each plural noun represents a human network whose presence in Nubia was care fully orchestrated: from Egyptian workers to foreign archaeologists and engineers to international bureaucrats. Elsewhere, I have described how this delicate orchestration can be understood as a design project that reconfigured the Nubian Desert into a new, massive exhibition space. Here it might suffice to note that this project was tacitly regulated by a logic of concentration and dissemination.20 The design began in 1959, when Unesco assigned a priority to each temple, designating some as of “first” or “second importance,” deeming the rest unsalvageable, and vetting proposals for new sites. Over the next twenty years, some temples were consolidated in four oases along the new lake, while others were dispersed individually as “ambassadors of Egyptian culture” in Western museums. To legitimate this work, Unesco invented an entirely new legal and bureaucratic framework for cul tural exchange. But despite Unesco’s guarantee of scientific and political neutrality, the overall effect of the temple movement was to optimize the number of tourists to the temples. In a sense, this redesign of the desert literalized what Gazzola called the passage “from the punctual to the global.”21 Once a sequence of points on a map, the monuments of Nubia became part of a global network wherein they retained their Nubian identity despite being dispersed across temporal and spatial discontinuities. So although the Abu Simbel temples were technically salvaged in situ (i.e., they were note, conceptually, relocated), they were fundamentally transformed by their movement, becoming the crowning moment of this new experiential complex—a new monumental infrastructure for a new nation-state.

Integrities

The task of salvaging Abu Simbel was never declared an international com petition, but it unfolded as a series of alternative schemes proposed by national delegations and assessed by Unesco. For the organization’s cultural officers, the project offered an opportunity to codify emerging international criteria for preservation, especially the concept of “integrity.” Borrowed from ecological discourse, the idea of integrity appeared especially promising to conservationists eager to expand their activities beyond the walls of individual monuments because it implied that a matrix of relationships exists between all the elements of a given site.22 But as in ecological thinking, the notion of integrity also provoked a constant slippage between ethical and scientific discourses. When applied to the moving of monuments, the term integrity alternately designated the morphology of a site, the material properties of an object to be moved, and the moral fiber of the person (or entity) doing the moving.

Unesco’s judging committees were composed of a variety of disciplinary representatives, and each national team making proposals was also an exper iment in collaboration. Most teams were led by engineers (who likely under stood integrity as a structural notion) but also included architects (for whom integrity was a site-planning strat egy) and sometimes preservation ists (who focused on the material integrity of objects). This intricate division of tasks—among engi neers and architects, individuals and institutions, nation-states and international organizations—was further complicated by an under lying debate over whether any modern human gesture should be legible in the desert. Here integrity, as a term applicable to environ mental systems, became entwined with integration, an aesthetic notion that had been developed by European art and architectural conservators since 1945.23 And while each team’s proposal can be read for its contribution to the new international discourse on integrity and integration, the rhetoric surrounding each scheme also reveals a preservation mentality strongly influenced by national traditions. These national discourses must be recalled along with the various salvage schemes proposed by each team— not in order to caricature them, but, on the contrary, to show how invisible these intellectual legacies had become in their home countries and how incon gruous and incompatible they suddenly appeared when forced to compete on an international stage. One irony of preservation history is that although preservation discourse became properly international as early as the mid nineteenth century, many of its practices and values remained nationally bounded well into the twentieth century, in part because the profession of preservation is largely administered by national state institutions.24

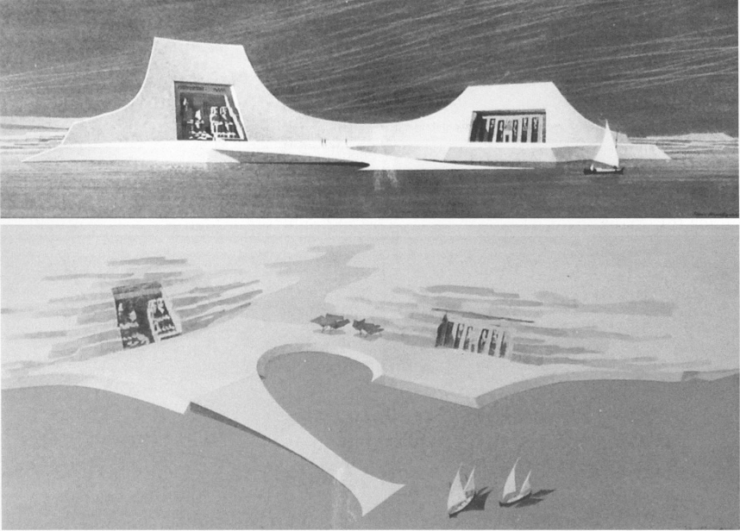

Damming, Lifting, Flooding, Floating

The first scheme to salvage Abu Simbel was proposed by the French engineering firm of Coyne et Bellier in summer 1960: to preserve the temple in situ by building a rock-fill dam—in some ways a copy of the Aswan High Dam—in front of the temples.25 This scheme would reintegrate the monu ments into the desert using the same technologies that had radically trans formed it. Coyne et Bellier were specialists in thin-shell concrete dams, but they left the design of the dam to French architect Albert Laprade, who sought to maintain what he called “the extraordinary harmony between the elements of this unique site.”26 Laprade devised an intricate choreography where visitors arrived by water at the level of the lake, descended along a sinuous scenic route to circumvent a shallow pool in front of the temples, and finally found themselves aligned with an axis that corresponded with the angle taken by the rising sun during a once-a-year illumination with the innermost shrine of the large temple.

Laprade felt no qualms about leaving a legible human gesture in the sand—so long as he deemed the gesture to be aesthetically continuous with the original setting. In this sense, he engaged in the French practice of “restoration” as it had been pioneered by Viollet-le-Duc and had continued to be fol lowed, in spirit, well into twentieth-century France: that is, the act of “re-instating a monument in a condition of completeness which could never have existed at any given time.”27 This “condition of completeness” had long been the French answer to the question of integrity, and Laprade evoked it when he called the site a “timeless landscape.” Yet completeness did not mean ideality. Having spent much of his career drawing and designing neo-orientalist buildings in an explicit rebellion against classicism, Laprade rejected circular geometry as “too majestic,” favoring instead an elliptical gesture that, he argued, created “a jewel-case” around the temples, “fusing” his work “into the landscape.” Found nature took the place of past architecture in this redefinition of restoration, as the new site was now described as having an “almost natural appearance.”28

But the architectural legibility of this “dam” scheme only concealed its weakness as an engineering proposal. As Unesco’s chief archaeologist soon realized, “unfortunately, dams are made to go across streams not to protect something on the side of the stream.”29 A pumping station, located far from view behind the temples, would perform most of the work of preservation. Financing this pumping would have been prohibitively expensive. Faced with the prospect of indefinite maintenance, within a few months Unesco decided to pursue an alternative plan that Piero Gazzola—the same Italian preservationist mentioned at the beginning of this article—had proposed during Unesco’s first fact-finding mission in October 1959.30

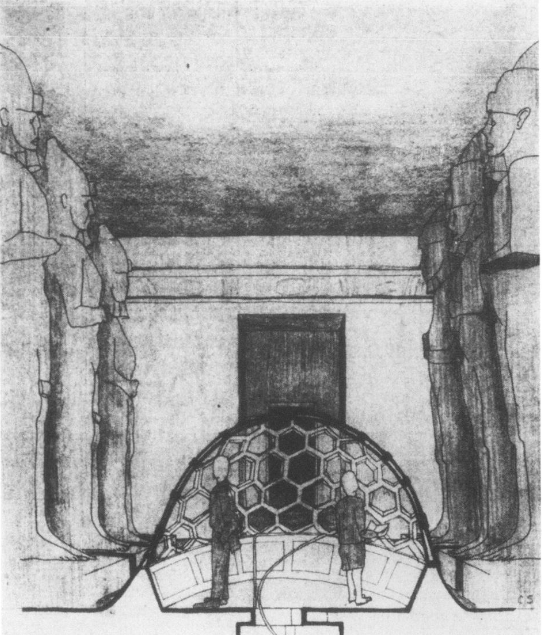

Gazzola was the first to propose “liberating” the temples of Abu Simbel from the mountain in order to “preserve the integrity of the temple by lifting it whole.”31 Influenced by an Italian tradition of painting restoration that distinguished between the epiderme and the struttura (the skin and the structure) of any work of art, Gazzola transformed the monolithic site into a building with a façade, a structure, and a site—or, as he put it, “the rock, the block and the box.”32 This preliminary sketch was further developed and officially presented to Unesco in October 1960: the temples would be severed from the cliff with three extended cuts into the rock, then encased in a gigantic concrete box and lifted about sixty meters, one centimeter at a time, by a grid of hydraulic jacks. This, too, implied a certain notion of integrity, similar to the one theorized by Cesare Brandi in his 1963 Theory of Restoration: the idea of preserving “the material wholeness of the work of art.” The difference between Italian wholeness and French completeness was that while Laprade had posited a timeless environment, Brandi identified a precise moment in time: restoration occurred at “the methodological moment in which the work of art is appreciated in its material form.”33 Restoration was a reenactment of aesthetic value.

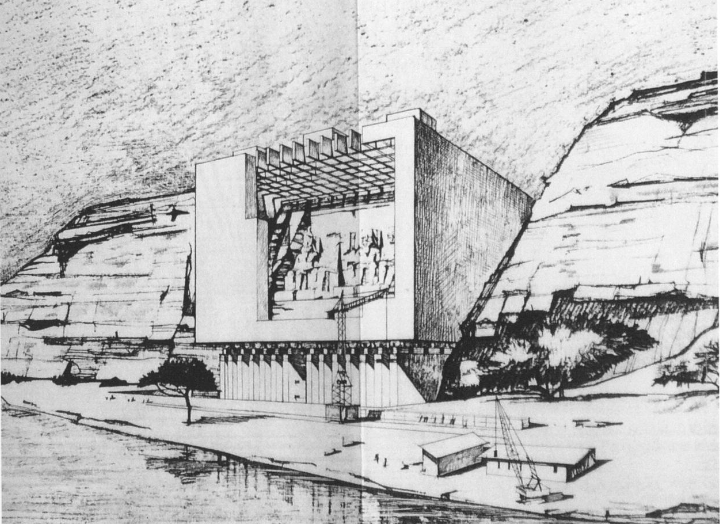

One advantage of the theory of reenactment is that it allows for modern technology to be exposed in preservation. Riccardo Morandi, the structural engineer who joined the Italian team, often contributed to preservation projects by designing modern structures for ancient monuments. For example, in his entry to the 1965 competition for the Tower of Pisa he proposed to build a scaffold around the tower, giving the medieval monument a visible modern crutch against which to lean. Similarly, Morandi proposed to reenact in Nubia the “wholeness” of Abu Simbel through the design of the concrete box to be poured around the temples to secure them during lifting. The box was designed in collaboration with the mathematician Gustavo Colonnetti so that the elasticity of the concrete—its ability to absorb mechanical forces— would be continuous with that of the sandstone.34 The elegance of the scheme lay in this momentary replacement of integrity with a calculated continuity between old and new materials. After all, this was the first scheme to propose a violation of integrity, a cut along three planes that would effec tively sever the relationships between the temples and their site.

One cannot overstate the technological heroism that permeated both the Italian team’s rhetoric and the publicity that Unesco derived from this scheme. Every component was experimental. Morandi drew dramatic sketches of the salvage that were circulated worldwide for fund-raising. But these renderings did surprisingly little to dramatize the process of lifting. In the most famous view, the hydraulic jacks are barely visible—the concrete box dwarfs them. Enframing the seated figures, the box appears to be a brutalist monument in its own right, similar to Morandi’s own concrete architecture. The only other perspective view Morandi submitted does not even show the temples, instead featuring the “tunnels” dug below the monument and occupied, in the architectural drawing, by two Nubian children. Undoubtedly they were drawn to demonstrate the monumental scale of the hydraulic jacks, but, as the only human beings in the whole scheme, they also serve an allegorical purpose of inhabiting “the cut” between the old and the new. Despite—or perhaps because of—the Utopian resonances of these drawings, the scheme never attracted enough funds for Unesco to begin con struction. By the middle of 1963, as the flooding grew near and fund-raising stalled, other nations volunteered their schemes.35