Concrete Planter Boxes

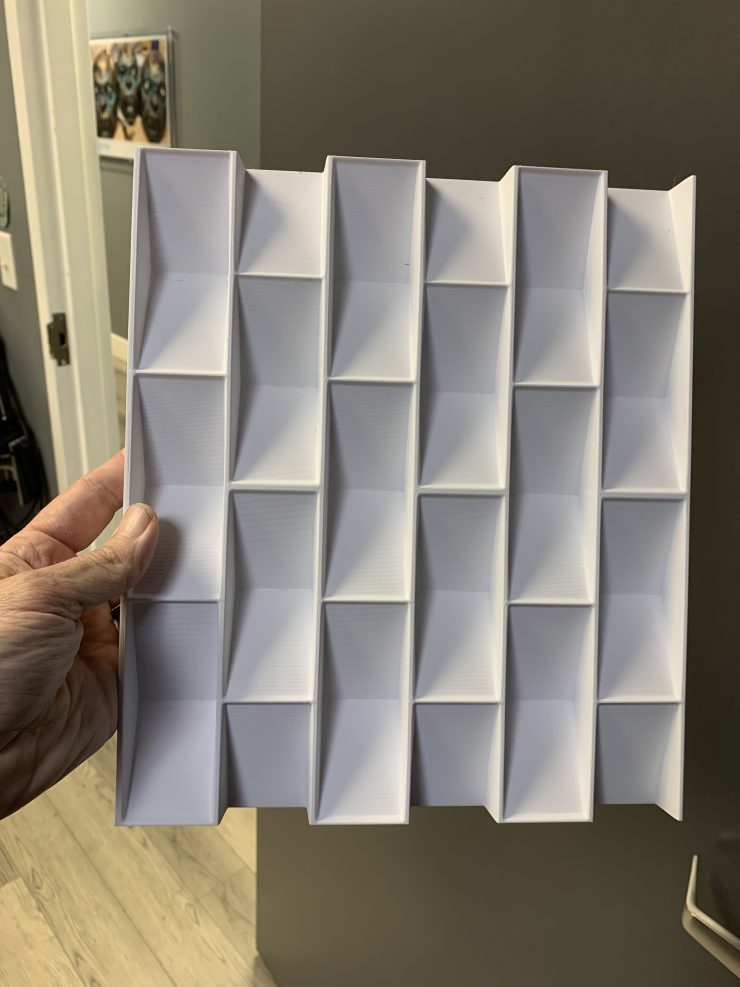

Working on the concrete planter boxes using a cast system from a mold.

Themed Entertainment and Architecture

Working on the concrete planter boxes using a cast system from a mold.

I’m always looking for ways to streamline my work and make it more efficient. That’s why I was inspired to design and 3D print a new product that simplifies the process of applying stucco.

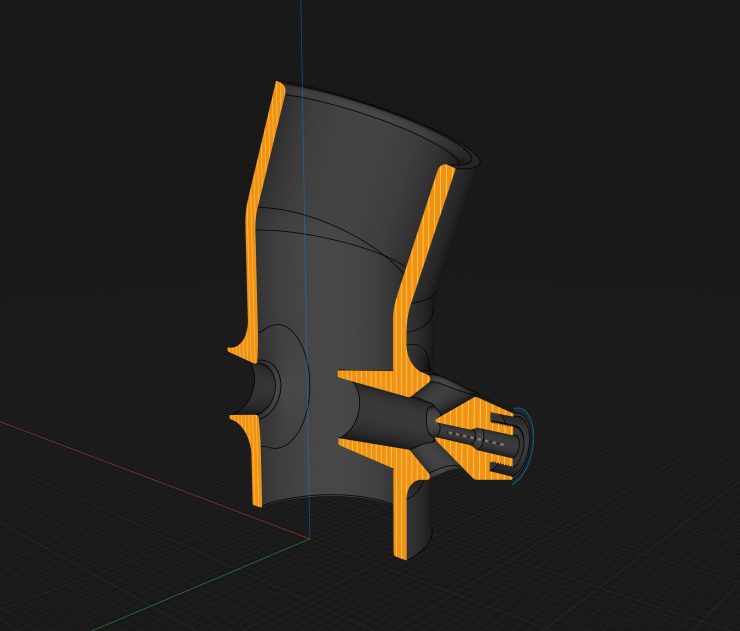

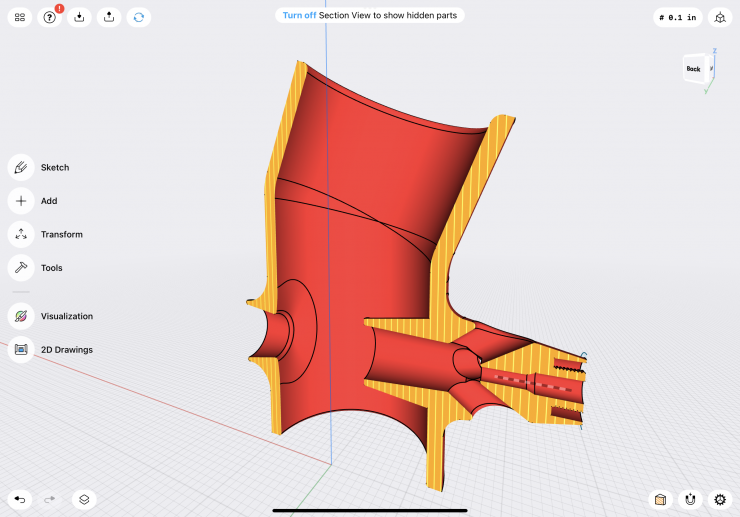

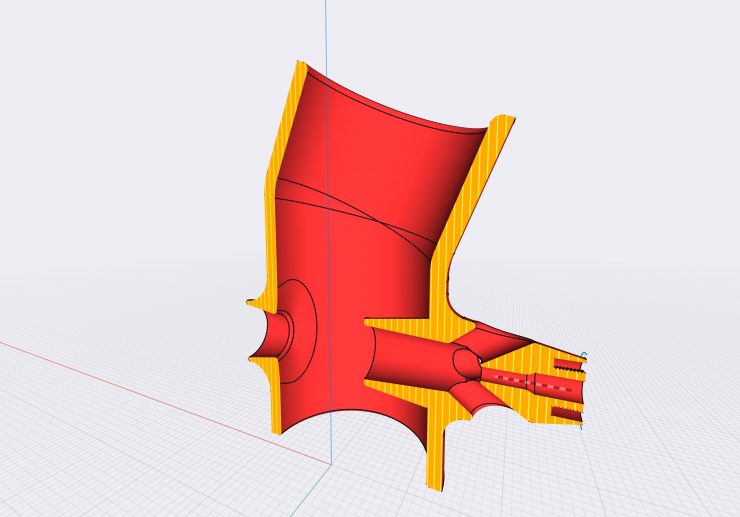

Traditional stucco application involves using a trowel to smooth the material onto a surface, but this can be time-consuming and labor-intensive. An alternative method is to use a spray gun, which allows for a more even application and faster coverage. However, the spray gun that I was using required several different bit types and wasn’t very user-friendly.

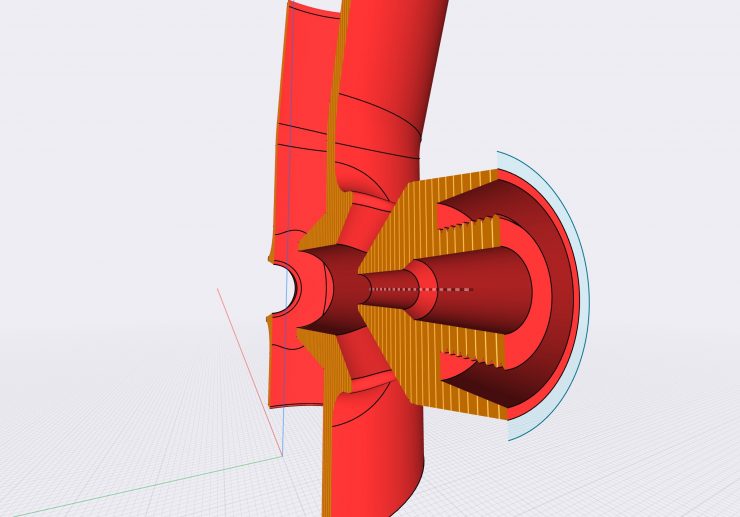

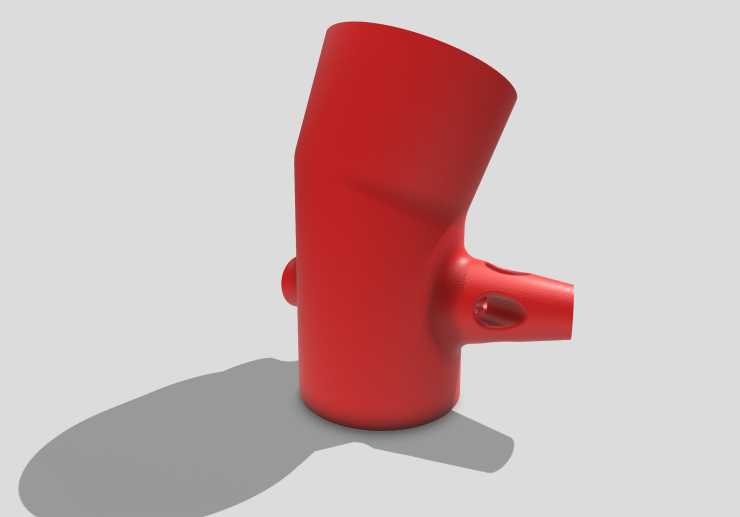

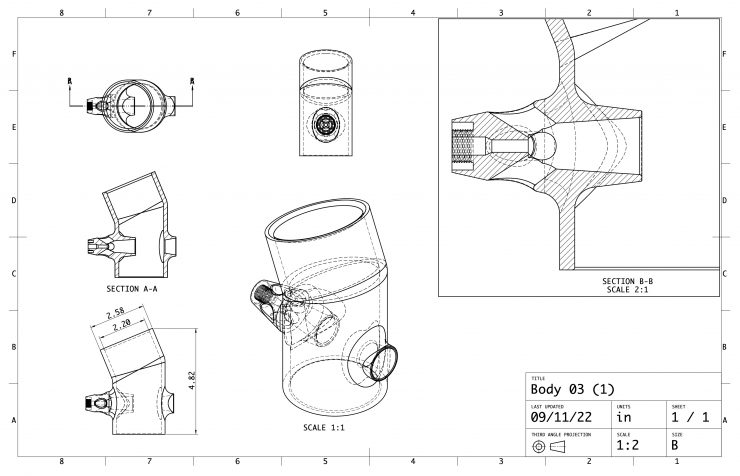

That’s why I decided to design my own spray gun specifically for stucco application. I took inspiration from the one that I was using, but I wanted to simplify the design and create a singular body that could be 3D printed.

To do this, I included all of the necessary parts into one single body and added a threaded nipple that could attach directly to a store-bought spray gun. This allowed me to create a more cohesive and user-friendly tool that could make stucco application easier and more efficient.

I’m excited to see how this new product performs in the field and hope that it can help other carpenters streamline their work as well. Stay tuned for updates on its performance!

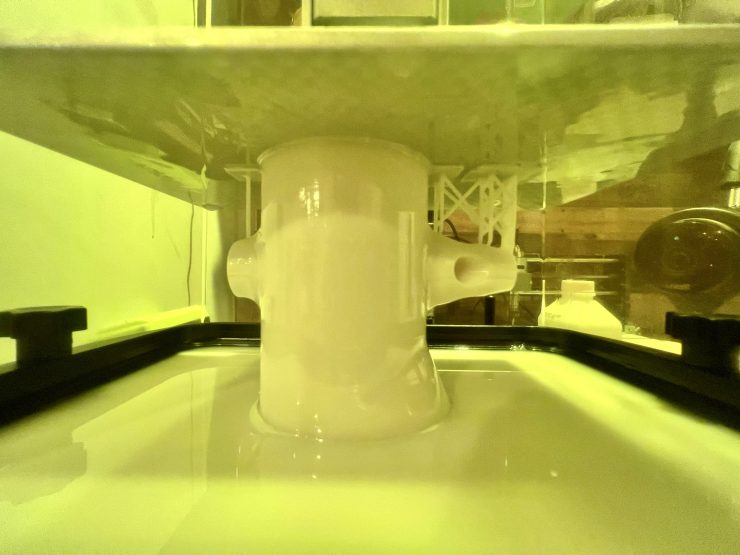

Here is the development in a few images of the prototype for my design of the 3D printed version. I will be testing in the coming days.

The 3-D print for the mold came out great. The next steps will be to produce a silicone mold so I can cast the aerated concrete.